Introduction

Renewed interest in carbon capture, utilization, and storage (CCUS) has exploded in the last 12 to 18 months in both the United States and Canada. This has been precipitated by the 45Q Carbon Capture Tax Credit in the United States and the federal carbon tax and Clean Fuel Standard in Canada. Large carbon dioxide (CO2) emitters from multiple sectors, such as power generation, ethanol production, fertilizer, lime, and oil and gas, will be under increasing policy and financial pressure to address their CO2 emissions. The Western Canadian Sedimentary Basin (WCSB), which stretches from northeastern BC to southwestern Manitoba, is one of the optimal locations in North America to pursue CCUS opportunities.

The WCSB is already home to several world-class commercial and research-oriented CCUS projects. These projects present a combination of CO2 enhanced oil recovery (EOR) and pure saline storage projects. Commercial projects include the Shell Quest Project and the Alberta Carbon Trunk Line. Research projects include the Carbon Management Canada (CMC) Containment and Monitoring Institute (CaMI) Field Research Station outside of Brooks, Alberta and the Petroleum Technology Research Centre (PTRC) Aquistore Project adjacent to SaskPower’s Boundary Dam facility near Estevan, Saskatchewan.

While CCUS projects are similar to oil and gas projects in terms of exploration and the technologies deployed, they also present unique technical and regulatory requirements that go beyond oil and gas projects. While there is a great deal of interest in CO2 flooding for EOR and the associated storage, most of the storage capacity in the WCSB lies within deep saline aquifers where relatively little geologic or reservoir characterization has taken place. As a result, a heavy emphasis is put on the site characterization for these projects. CCUS projects are also required to have risk-based measurement, monitoring, and verification (MMV) plans that monitor the development of the CO2 and associated pressure plumes in the storage formation over time, and Closure Plans. The MMV plan must monitor the overburden for any indications of CO2 or brine migration out of the storage complex that might endanger potable groundwater or mineral resources. MMV plans typically deploy a range of monitoring technologies, including pressure monitoring, fluid sampling and geochemical analysis, and indirect geophysical methods to meet regulatory requirements and manage project risks related to storage, and address public perception concerns.

Potential for CCUS in Western Canada

For a saline formation to be considered an ideal candidate for CO2 storage, it should fulfill several requirements. Open saline formations bounded by continuous impermeable layers that prevent the migration of CO2 out of the storage formation are preferred over structural or stratigraphic traps with closure, in part to maximize storage capacity. Saline formations must be located at depths below 800 m total vertical depth (TVD) in order for the CO2 to remain in a dense, supercritical state (Intergovernmental Panel on Climate Change [IPCC], 2005). At depths shallower than 800 m TVD, CO2 will be a gas phase, and CO2 storage security and technical feasibility decrease sharply. In Alberta, the storage formation must be located at a depth of more than 1000 m TVD, and the fluids must have greater than 4000 mg/L total dissolved solids (TDS) (Province of Alberta, 2011). To reduce the risk of CO2 migrating up along wellbores that penetrate the storage formation, a CCUS project should be sited in an area with a minimum number of well penetrations.

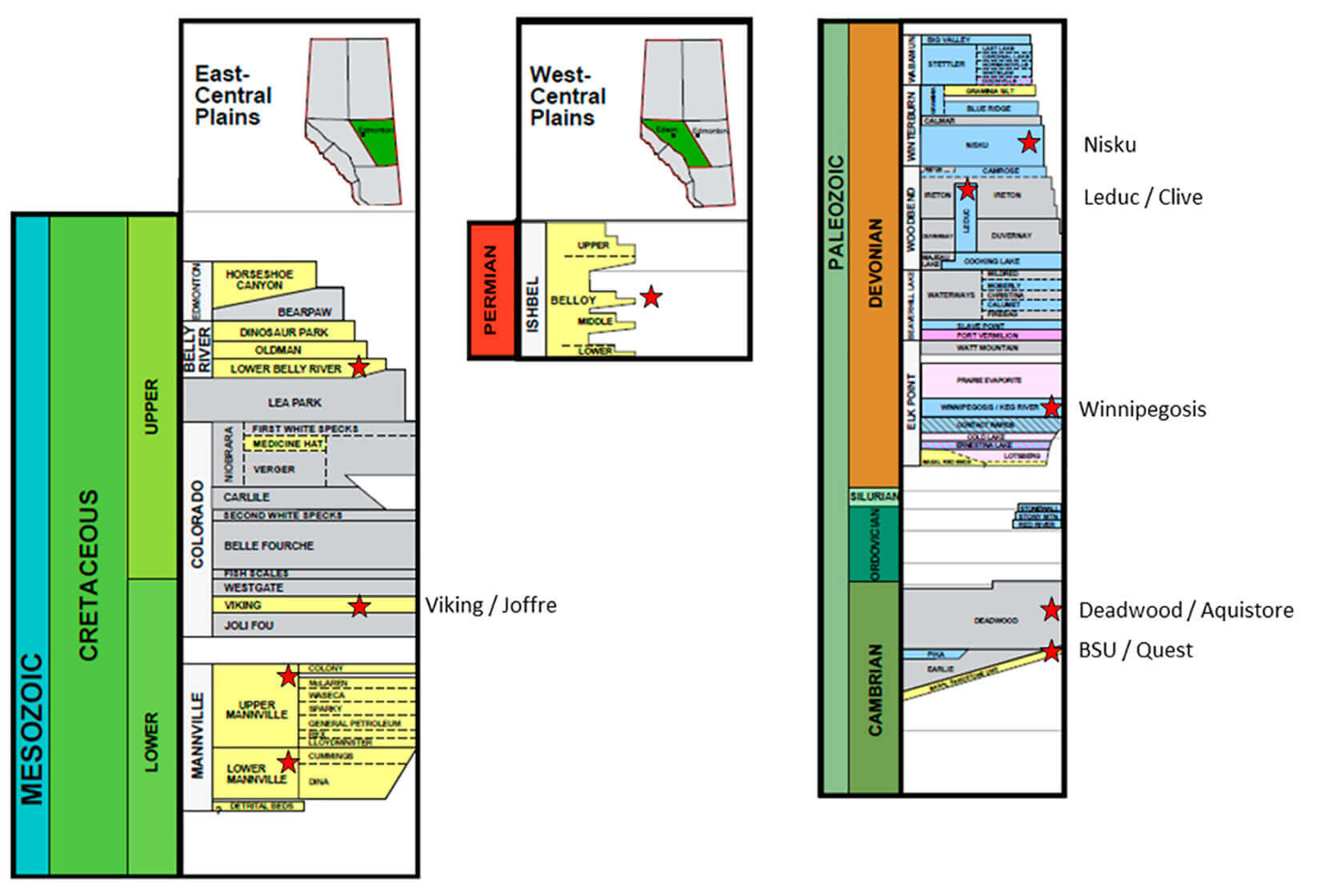

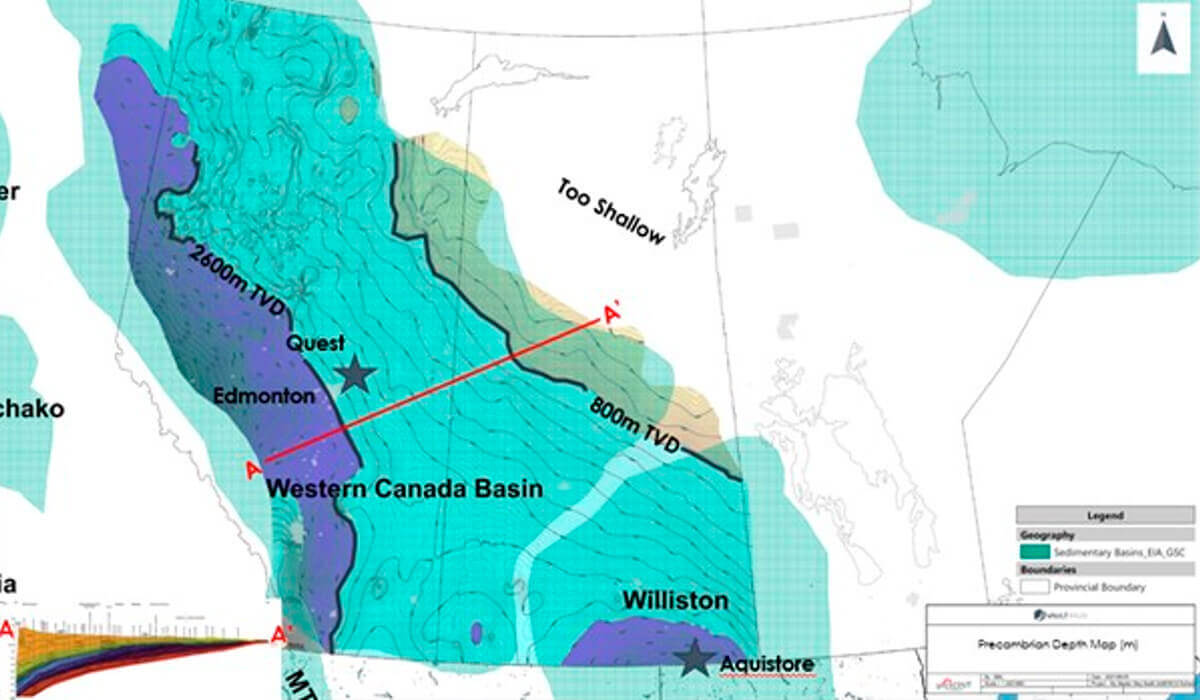

The WSCB contains extensive deep saline formations that are the largest targets for CCUS in western Canada (Dahowski and Bachu, 2007). In the WCSB, there are good potential candidates for CO2 storage in saline aquifers in the Cambrian, Devonian, Permian, Jurassic, and Lower and Upper Cretaceous aged sediments in different parts of the basin (Figure 1). Regional mapping is required in order to determine the depositional extent and depth of some of the formations. A saline aquifer with good potential in some parts of the province may be too shallow to maintain supercritical conditions in other parts of the province, or too deep to provide adequate reservoir properties for storage. For example, the Shell Quest Project outside of Edmonton, Alberta injects CO2 into the Cambrian aged Basal Sandstone Unit (BSU), directly overlying the Precambrian Basement at a depth of 2000 meters (m). The same formation (BSU) lies at depths of more than 5000 m along the deformation front in western Alberta (Figure 2) and exceeds 3200 m in southeastern Saskatchewan. Low porosities and permeabilities and the depth of the formation do not make it an attractive target in this area of Alberta.

Other formations of potential interest in Alberta include the Leduc, Nisku, Belloy, Sawtooth, Ellerslie, Mannville, Cardium, and Belly River formations (Figure 1). Depositional settings that encourage formations with a large aerial extent are the most sought-after storage. The Cardium Formation of the Pembina Field in central Alberta and BSU in mid-eastern Alberta are good examples of laterally extensive saline formations with storage potential. Historically, CO2 EOR targets have included localized high-quality oil reservoirs, such as the Viking Formation in the Joffre Field (clastic high-energy shoreface) or the Leduc Formation in the Clive Field (carbonate reef complex).

The Williston Basin spans southern Saskatchewan, western Manitoba, eastern Montana, and western North and South Dakota (Figure 2). The Williston Basin also has a basal sandstone unit that is commonly referred to as the Deadwood Formation, which resides deep in the basin. However, there is potential to store CO2 in shallower horizons of the Madison Group of the Mississippian-aged sediments that include the Weyburn – Midale Formation.

CCUS Projects in Western Canada

Shell Quest

The Quest CCS facility, near Edmonton, Alberta, is the world's first commercial-scale CCS facility applied to oil sands operations (Figure 2). Carbon dioxide produced at the Scotford Upgrader is captured, compressed, and transported to a storage location near Thorhild, Alberta.

The project began injecting CO2 in August 2015, and in 2020 achieved a milestone of 5 million tonnes (Mtonnes) of CO2 injected. The project has safely stored more than any other onshore CCUS facility in the world (Alberta Department of Energy, 2020). Yearly summary reports for various aspects of the Quest Project can be found on the Alberta Government website (Alberta Government, 2021). These reports include information and updates on the MMV technologies that have been deployed for the project, such as atmospheric, shallow and deep groundwater sampling, wellhead and downhole pressure gauges, distributed temperature sensor (DTS) fibre optic cables, time-lapse vertical seismic profile (VSP) surveys, and downhole microseismic monitoring.

Alberta Carbon Trunk Line / Enhance Energy (ACTL)

The ACTL is a central Alberta CCUS project currently under development in phases. The project is a partnership between Wolf Midstream, Enhance Energy, and two industrial emitters in Alberta’s industrial heartland near Fort Saskatchewan, Alberta (Alberta Carbon Trunk Line, 2021). Approximately 1.6 Mtonnes/ year of CO2 is captured from the Sturgeon Refinery and Nutrien’s Redwater Fertilizer facility via a 240 kilometer (km) pipeline to the Clive oil field for enhanced oil recovery (EOR) (Figure 3). Once fully operational, the entire Clive field will be under CCUS development. The CO2 EOR is expected to help recover 15 to 20% of the original oil in place, with much of the injected CO2 permanently stored (Alberta Carbon Trunk Line, 2021).

SaskPower Boundary Dam / PTRC Aquistore Project

In the fall of 2014, the SaskPower Boundary Dam Station near Estevan, Saskatchewan, became the first power station in the world to deploy carbon capture technology (SaskPower, 2021). As of July 2021, approximately 4.17 Mtonnes of CO2 have been captured from Unit 3 of SaskPower’s coal-fired plant (SaskPower, 2021). Most of the captured CO2 has been sent via pipeline to be utilized for CO2 EOR in the Weyburn – Midale Field currently operated by Whitecap Resources Inc. and has been under a CO2 flood for over 20 years.

There is also a small CCUS research project adjacent to the Boundary Dam facility that is operated by the PTRC (Petroleum Technology Research Centre) in Regina, Saskatchewan. The Aquistore Project is focused on testing MMV technologies on CO2 that is injected into the Deadwood Formation about 3,400 m TVD (Petroleum Technology Research Centre, 2021). This project has an extensive MMV program that uses a combination of traditional and novel technologies. Seismic technologies utilized at the site include a sparse, permanent geophone array used for time-lapse surface seismic monitoring and a casing deployed distributed acoustic sensing (DAS) fibre optic cable in the observation well used for time-lapse VSP surveys (White et al., 2016).

CMC CaMI Project

CMC operates the CaMI Field Research Station near Brooks, Alberta. Small volumes of CO2 are injected into the Basal Belly River Sandstone at a depth of approximately 300 m (Lawton, 2017). The field station is used to test new MMV technologies on a small volume, shallow injection interval that has been designed to simulate a small leakage accumulation associated with a deeper storage site. New protocols and technologies for MMV regulatory compliance and leak detection are rigorously tested to drive the improvement of processes intended to alleviate public concerns about the safety of CCUS technology. MMV technologies used at this site include DTS and DAS fibre optic lines, downhole and surface-based microseismic monitoring, a range of electromagnetic and electrical resistivity tools, well logging, surface and borehole seismic surveys, fluid sampling and analysis, soil gas, and atmospheric monitoring.

Process for Permitting a CCUS Project in Alberta

In May 2021, Alberta Energy released an information letter on carbon sequestration tenure management stating that the province would be issuing carbon sequestration rights through a competitive process that would start with a Request for Expression of Interest (REOI). In September 2021, Alberta Energy released the guidelines for the REOI process with a deadline for submittal of October 12, 2021 (Alberta Energy, 2021). Alberta Energy will use the REOI process to assist in planning for the Request for Full Project Proposals (RFPP) that is expected to be released in December 2021. The submission of an REOI is not required in order to proceed with an RFPP in December.

While there are nearly a dozen regulatory documents that regulate CCUS projects in the province of Alberta, three of the primary regulatory documents that affect the development of CCUS projects are the Mines and Minerals Act Chapter M-17, Alberta Regulation 68/ 2011: Carbon Sequestration Tenure Regulation, and the AER Directive 51: Injection and Disposal Wells. The Carbon Sequestration Tenure Regulation defines the requirements for evaluation permits and carbon sequestration permits.

properties of a formation to determine if it is suitable for a period of five years as per the Mines and Minerals Act (115). A monitoring, measurement, and verification (MMV) plan is a required component of the evaluation permit application, and it must be approved by the regulator prior to any operational activities taking place in the proposed permit area (Province of Alberta, 2020). Once the permit application is approved, the operator must submit yearly reports to the regulator showing compliance with their proposed MMV plan. MMV plans are valid for three years, after which they must be re-assessed and renewed with the regulator.

A carbon sequestration permit allows an operator to inject CO2 in the subsurface as per the Mines and Minerals Act (116), in addition to allowing an operator to drill wells and evaluate formation properties. Carbon sequestration permits are granted for a period of 15 years, with an additional option to renew for another 15 years. An MMV and site closure plan are required components of a carbon sequestration permit application, and both must be renewed with the regulator every three years. Once the permit is granted, the operator must pay into a Post-closure Stewardship Fund.

Risk-Based Site Characterization and MMV Plans

Risk Assessment and Management

A risk assessment and management plan is a critical part of a CCUS project. It should be dynamic and evolve over time through the site characterization, pre-injection, operational, and post-injection phases of a project as new data is acquired and assessed (Table 1).

| Project Phases | Risk Management, Site Characterization, and MMV Activities |

|---|---|

| Table 1. CCUS project phases and associated risk management, site characterization, and MMV activities. | |

| Site Characterization |

|

| Pre-Injection Baselines |

|

| Operations |

|

| Closure/ Post-Injection |

|

| Post Closure |

|

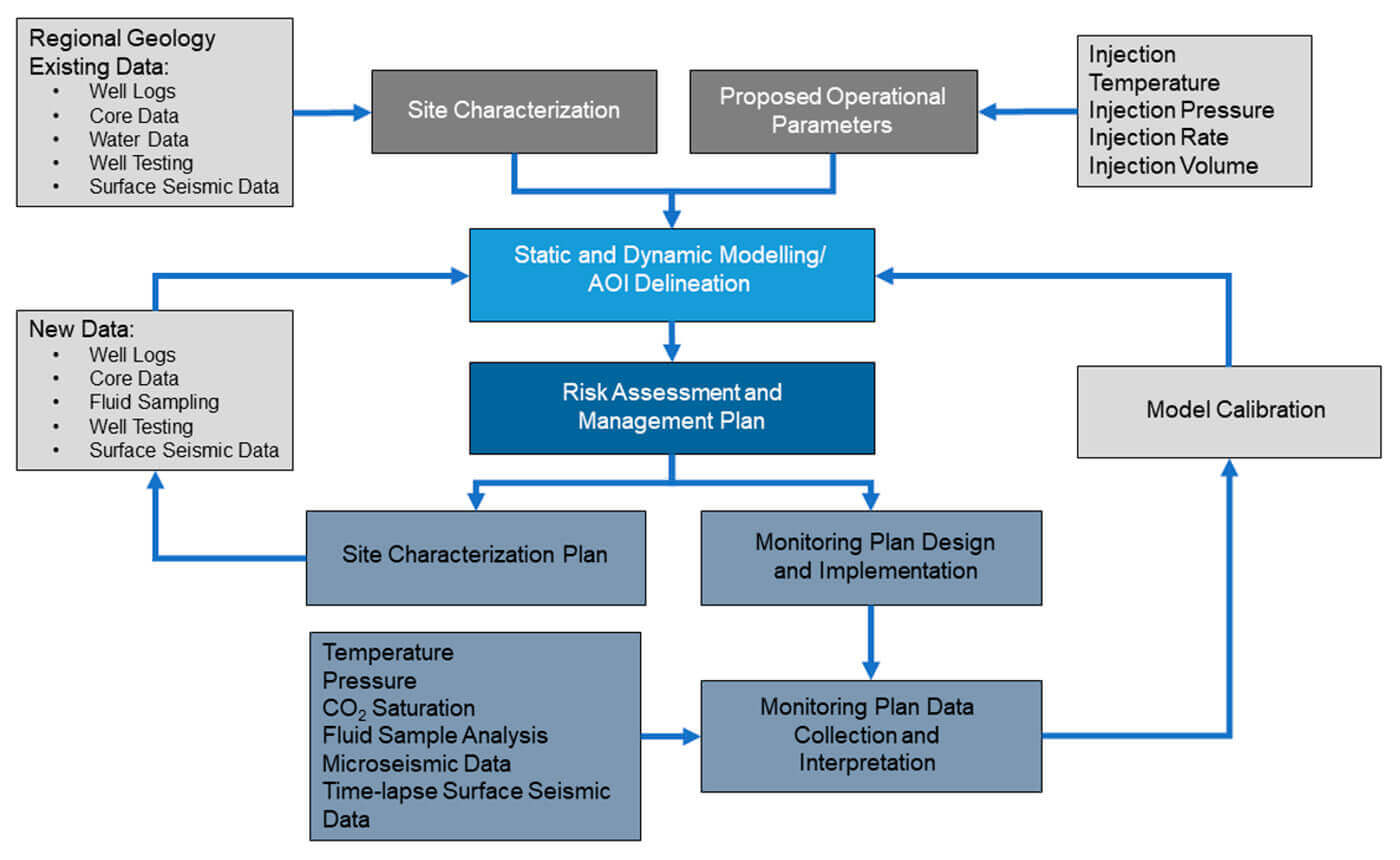

The risk assessment process for CCUS projects can be approached using several methods, including Features, Events, and Processes (FEP) or bow-tie analysis; however, one of the primary goals of the risk assessment is to identify subsurface risk scenarios that can be managed through site characterization and MMV activities. As such, the risk management plan should be closely linked to the site characterization and MMV plans throughout all of the project phases (Figure 4). Initially, the risk management plan should identify areas of subsurface uncertainty at a site which will aid in determining the site characterization activities used for a particular project. With regard to the MMV plan, the effects and changes related to the occurrence of a particular scenario should be identified so that appropriate technologies can be selected to monitor changes should they occur over the life of a project.

Site Characterization Plan

While the Carbon Sequestration Tenure Regulation does not explicitly require a site characterization plan, a successful evaluation permit will require a current summary of the geologic understanding and suitability of the proposed storage complex and the rationale for the proposed area of interest (AOI). The storage complex can be defined as the subsurface geological system comprising a storage unit and primary and possibly secondary seal(s), extending laterally to the defined limits of the CO2 storage operation (CSA, 2012); it may also include a bottom seal.

The site characterization phase of a project should involve the collection of existing datasets in a potential AOI to build an initial static earth model and complete dynamic modelling to predict the extent of the CO2 and associated pressure plumes for a given injection rate over the operational phase of a project (Table 1). Preliminary estimates of injectivity, injection pressure, and storage capacity should also be made at this time. This modelling work will be used to inform the early risk assessment and scenario analysis (Figure 4). Based on the uncertainties identified through the risk assessment, a range of activities may be undertaken to further characterize the geological, geochemical, and geomechanical properties of the storage complex and the overburden within the evaluation permit boundaries (Table 2).

| Characterization Activity | Parameters Obtained |

|---|---|

| Table 2. Potential site characterization activities and the potential parameters obtained. | |

| Well Logging | Porosity, permeability, lithology, stress, fracture characterization, Poisson’s Ratio, Young’s Modulus, temperature gradient, fluid saturations |

| 3D Surface Seismic Data | Features that pose a risk to long-term CO2 containment, structural and stratigraphic features that may affect CO2 and pressure plume development, rock properties away from the project wells |

| Core Analysis | Geological and geomechanical properties of the storage formation and potential seals |

| Fluid Sampling | Baseline aqueous geochemistry and stable isotopes for the storage formation, overlying aquifers, deepest potable waters, and near surface groundwater |

| Reservoir Testing | Initial formation pressure, injectivity, boundary conditions, average permeability, fracture pressure |

| Induced Seismicity | Baseline monitoring of induced seismicity in the AOI |

As long-term containment and storage security are key components of a CCUS project, the characterization of the primary and secondary seals is just as important as it is for the storage formation. In addition, characterization of the baseline aqueous geochemistry of the fluids in storage formation and any overlying aquifers that may be impacted by future out of zone migration of CO2 such as the closest overlying aquifer above the storage formation, the deepest aquifer with potable water, and near surface groundwater sources. This can be particularly important for near-surface groundwater sources that can show a great deal of seasonal or yearly variability depending on weather conditions and rainfall amounts.

Once the new data has been collected and analyzed, it should be used to update the static and dynamic modelling and re-evaluate the predicted CO2 plume and associated pressure plume (Figure 4). The risk management plan should also be updated incorporating the actions that have been taken through the site characterization activities (Table 1); this may also result in revisions to the MMV plan.

MMV Plan

The Carbon Sequestration Tenure Regulation is not prescriptive regarding requirements for MMV plans, except for AER Directive 51 requirements for injection and disposal wells. AER Directive 51 requirements include (Alberta Energy Regulator, 1994):

- Proof of hydraulic isolation of the injection zone from useable water and mineral resources

- Casing integrity log

- Annual packer isolation test

- Injection pressure limited to 90% of the formation fracture pressure

Beyond the Directive 51 requirements, the MMV plan should be developed in conjunction with the risk management plan for a project to reduce the risks associated with CO2 storage in the subsurface. The goals of the MMV plan should include (Canadian Standard Association, 2012):

- Fulfillment of regulatory requirements set out in the legislation of the jurisdiction

- Documentation and demonstration that the project risks identified by the project’s risk management plan are being managed

- Provide the technical rationale for the selection of specific monitoring technologies

- Demonstrate that the project will not interfere with mineral recovery or potable waters

- Ensure that the injection well is operating as planned

- Provide data to validate and calibrate the geological and dynamic models used to predict the development of the CO2 and pressure plumes within the storage formation

- Enable the potential transfer of long-term liability through evidence of model conformance to MMV data, containment of CO2 within the storage complex, and verification of the lack of adverse effects to health, environment, and resources

he MMV plan should be adaptive over time in that the plan can be adjusted to respond:

- As project risks evolve over the course of the project

- If significant differences between the monitoring data and predicted dynamic modelling results are identified

- If key monitoring techniques indicate anomalous results related to well integrity or the loss of CO2 containment

Monitoring activities can be broken into three monitoring categories based on various objectives: operational, verification, and assurance monitoring (Table 3). Operational monitoring focuses on monitoring day-to-day injection operations. Verification monitoring confirms that the CO2 remains contained within the storage complex and tracks the CO2 and pressure plume development over time to provide data for model calibration. The goal of assurance monitoring is to monitor the surface and near-surface for potential changes that may occur as a result of CO2 migration towards the surface. It is common for a particular monitoring technology to contribute to more than one monitoring category. For instance, a DTS fibre optic cable can be used for both operational and verification monitoring depending on how and where it is deployed.

| Operational Monitoring | Verification Monitoring | Assurance Monitoring |

|---|---|---|

| Table 3. Monitoring categories and their monitoring objectives. | ||

| Injection Monitoring: | Storage Complex Integrity: | CO2 Out of Zone Migration: |

| Flow rates Pressures (well head, annulus, bottom hole) Temperature (well head and bottom hole) CO2 quality and impurities |

Well integrity Caprock integrity (mechanical and chemical) Induced seismicity |

Into Overburden To Surface |

| Quantification of Injected CO2: | Basin Impact: | HSE Impact: |

| Quantify mass of injected CO2 | Pressure plume development Displacement of brine |

Freshwater aquifers Soils Ecosystems Atmosphere |

| CO2 Displacement and Fate: | Quantification of Leaks: | |

| Plume development Trapping mechanisms Capacity assessment |

Estimate amount of CO2 emitted at surface | |

For a particular project, MMV technologies can also be broken into key or primary technologies that are deployed at the start of a project and contingency technologies. Contingency technologies would be deployed if anomalous results are obtained through the key monitoring technologies or should a trigger event occur. For instance, a deflection in the slope of a new temperature log that deviates from previous temperature log trends may indicate a problem with well integrity that would need to be investigated through other means. Alternately, if steady pressure increases were observed in a saline formation above the primary storage formation, it may be appropriate to begin or increase the fluid sampling in that formation to look for geochemical markers that may indicate that CO2 had migrated into the formation. The results of the fluid sampling may further trigger the need to acquire a time-lapse 3D seismic survey to try to determine the extent of a leakage accumulation.

Given the diverse monitoring categories and objectives for an MMV Plan, a large range of MMV technologies typically need to be deployed for a CCUS project. The MMV technologies may include:

- Corrosion monitoring

- Continuous wellhead and downhole pressure and temperature monitoring

- Fluid sampling for aqueous geochemistry and stable isotope analysis

- Time-lapse temperature and pulsed neutron capture logging

- Microseismic monitoring

- Time-lapse seismic surveys

- Near-surface electromagnetic surveys

- Soil gas surveys

- Atmospheric monitoring

Closure Plans

A Closure plan must be submitted as part of a carbon sequestration lease application. This plan must be updated and renewed every three years. During the closure or post-injection phase of a project, the risk of CO2 migration beyond the storage complex begins to decrease as pressures within the storage formation begin to dissipate. However, the operator will be expected to continue MMV activities for several years until the project can clearly demonstrate to the regulator that the injected CO2 is being contained in the storage complex as well as conformance between the MMV data and the dynamic models of the CO2 and pressure plume behaviour.

To obtain a Closure Certificate from the regulator, a project will need to provide:

- A summary of all of the activities conducted for the project since the carbon sequestration lease was issued

- Quantity of CO2 injected

- An evaluation of whether the CO2 has behaved in a manner consistent with the dynamic modelling

- The most recent geologic and dynamic modelling of the CO2 and pressure fronts

- Description of decommissioning, abandonment, and reclamation activities

- Inventory of all reports submitted to the regulator

- Recommendations on continued MMV activities once the Closure Certificate has been awarded.

Once the Closure Certificate has been obtained, the long-term liability for the project will be transferred to the Province.

Summary

The WSCB contains extensive deep saline formations that are the largest targets for CCUS in western Canada. The ideal saline formations for CCUS are open formations located at depths below 1000 m, have greater than 4000 mg/L TDS, and have a limited number of well penetrations. There is also a range of oil and gas fields that are candidates for CO2 EOR that would ultimately permanently store the injected CO2. The WCSB is home to several world-class commercial and research-oriented CCUS projects, including the Shell Quest Project, the Alberta Trunk Line, the CMC CaMI Field Research Station, and the PTRC Aquistore Project. The Quest Project, CaMI Field Research Station, and the Aquistore Project all have extensive MMV programs associated with the projects.

Alberta has several CCUS specific regulations including the Mines and Minerals Act Chapter M-17, Alberta Regulation 68/ 2011: Carbon Sequestration Tenure Regulation, and the AER Directive 51. The Carbon Sequestration Tenure Regulation defines the requirements for evaluation permits and carbon sequestration permits for projects. The regulatory requirements for evaluation and carbon sequestration permits that differ from traditional oil and gas projects include the need for risk-based site characterization and MMV plans and Closure Plans that must be approved by the regulator prior to commencing any operational activities covered by the permit.

A risk assessment and risk management plan is a critical component of the CCUS project. The plan should be dynamic and evolve over time through the site characterization, pre-injection, operational, and post-injection phases of a project as new data is acquired and assessed. The results of the initial risk assessment and scenarios should be used to guide the development of site characterization and MMV plans for a project. A range of activities may be undertaken to characterize the geological, geochemical, and geomechanical properties of the storage complex and the overburden within the boundaries of a permit area. New data should be used to update the static and dynamic modelling and re-evaluate the predicted CO2 plume and associated pressure plume. The MMV plans should be risk-based and adaptive over the life of a project. They are essential in demonstrating the containment of CO2 within a storage complex and for providing data to calibrate the static and dynamic models over the life a project. MMV technologies that may be deployed for a project include continuous wellhead and pressure monitoring, time-lapse well logging, fluid sampling to analyze aqueous geochemistry and stable isotopes, microseismic monitoring, and time-lapse seismic surveys. MMV activities typically continue through the closure phase of a project. Ultimately, a project will need to demonstrate the continued containment of CO2 within the storage complex and conformance between the MMV data and the dynamic models of the CO2 plume and associated pressure plume to obtain a closure certificate for the project and transfer of project liability to the province.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article