Summary

Heavy oil recoveries in most heavy oil reservoirs in Western Canada are usually less than 10% under primary recovery schemes (native pressure and oil saturation). Thermal methods have been utilized in the Saskatchewan heavy oil region by many operators as a profitable alternative to traditional enhanced oil recovery (EOR) schemes. Petrobank Energy and Resources Ltd. utilizes Toe to Heel Air Injection (THAI®), a patented in-situ combustion technology, to recover large amounts of the remaining resource while upgrading the oil in-situ. Lab results show that THAI® can recover up to 65% with an average upgrade of ~8o API, while field results show an average of ~4o API upgrade with recovery amounts still being monitored with time (Kendall and Wikel, 2011).

Thermal recovery methods are well suited to monitoring with time-lapse seismic. Published data shows that heavy oil velocities decrease with added temperature in the lab (Han and Batzle, 2006) and other time-lapse case studies show observable and tested time-lapse responses when monitoring THAI® with seismic (Kendall, 2009; Kendall and Wikel, 2011). In addition, 4D-3C seismic can aid in caprock integrity monitoring via overburden stress change through time (Wikel et al, 2012).

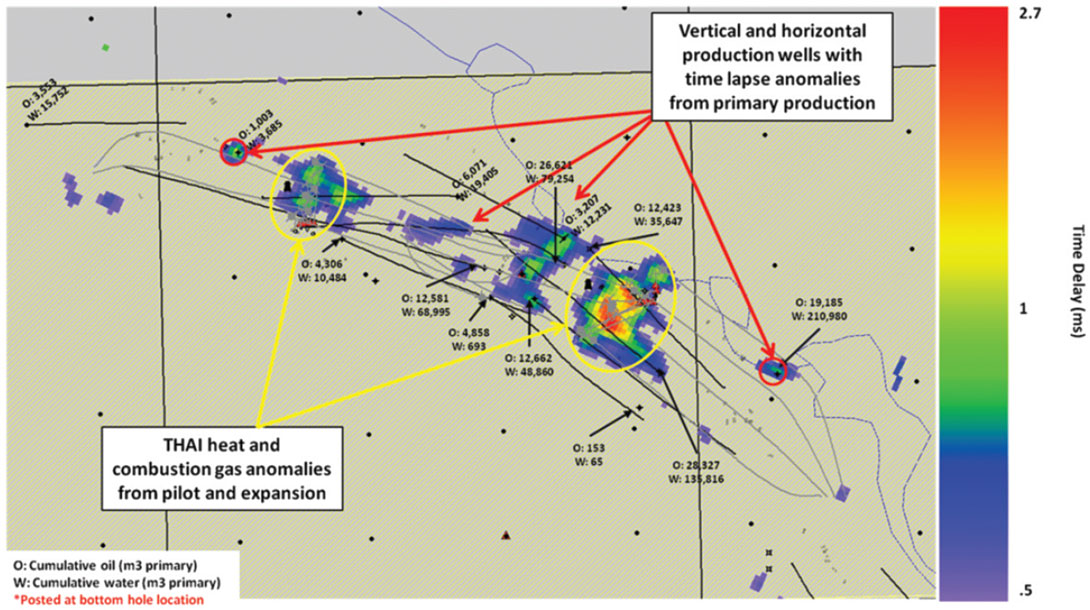

This case study will outline the analysis of a non purpose-shot 3D baseline (1995 regional exploration survey) being pre-stack interpolated and re-processed to act as a baseline to a recent purpose-shot time-lapse (2011) near Petrobanks Kerrobert, Saskatchewan THAI® facility. Results show an observable PP time-lapse response due to the THAI® process, which allows us to monitor temperature and gas migration in the reservoirs of active THAI® projects. In addition to this, PP time-lapse anomalies are present around legacy primary production wells which are interpreted to be a result of secondary gas and/or the presence of wormholes (channelling phenomenon from sand production in cold heavy oil production, or CHOPS). PS splitting occurs in the reservoir around two wells that have the largest injection/production rates in the field (PS splitting being the difference in arrival times of the fast (PS1) and slow (PS2) converted wave arrivals). This correlation implies that the thermal methods stress effect on the reservoir can be monitored by utilizing PS splitting attributes statically and possibly in the time-lapse domain.

Introduction

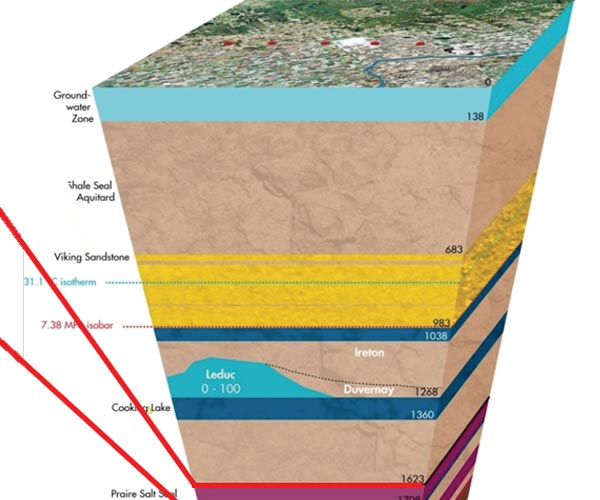

Heavy oil reservoirs in Saskatchewan present a relevant case study in primary recovery versus secondary recovery potential in the world of heavy oil (heavy oil being oils that have a 10- 22° API gravity). In most heavy oil reservoirs, the oils viscosity is too high (>5,000 cP) under native reservoir conditions to flow efficiently and at commercial rates for long periods of time (>5 years). The water saturation, viscosity contrast of oil to water, drawdown, and relative permeability of the oil to water can also cause early water coning and large amounts of water production through time. To further complicate matters, large amounts of sand can also be produced. Oil recovery in Petrobanks’ Kerrobert field from primary production is only 1.5%, which leaves a substantial amount of resource for secondary recovery schemes. In light oil reservoirs, secondary recovery most often takes the form of water flooding or natural gas injection, while CO2 floods and polymer floods are employed for heavier oil EOR schemes or tertiary recovery. Most heavy oils, however, have high viscosities that limit the effectiveness of the aforementioned EOR schemes (Thomas et al, 1999). Therefore, many operators in Western Canada opt for thermal methods to recover the heavy oil remaining in the reservoir after primary production has become uneconomic.

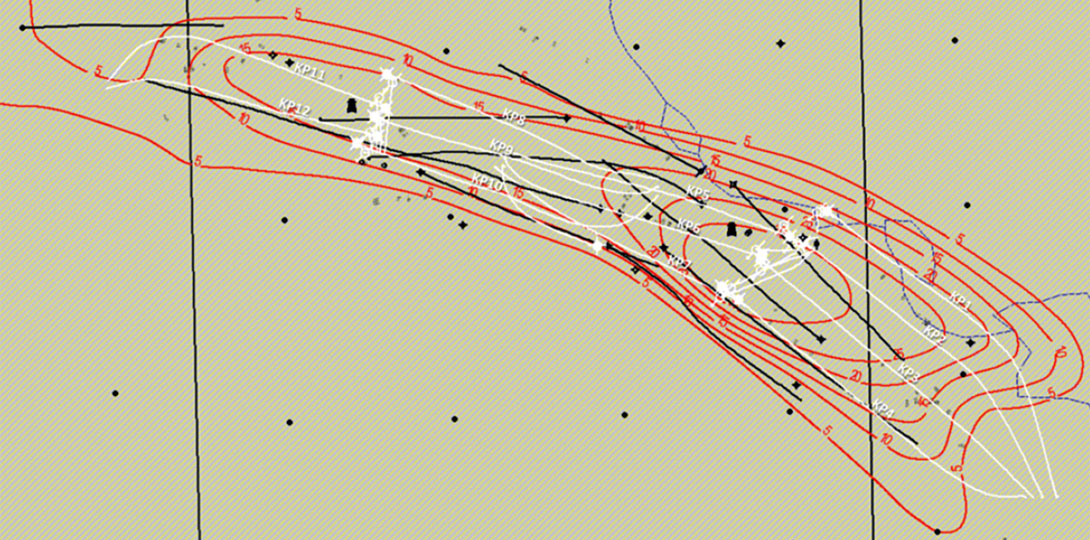

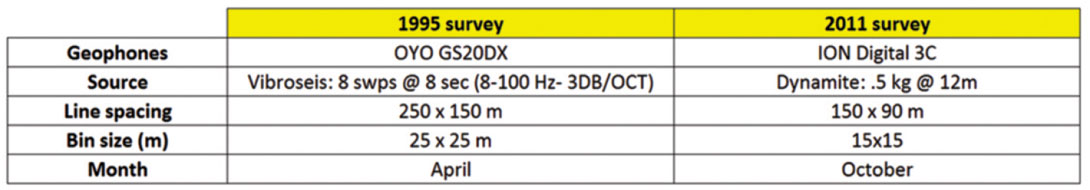

The Mannville Group within the Saskatchewan heavy oil region is an ideal target for secondary production, as primary production produced only 1.5% of original oil in place in the Kerrobert Waseca reservoir of interest (Figure 1). This low production is due mostly to the high viscosity of the oil and presence of bottom water. The Waseca sandstone channel is the target reservoir in this case study, reservoir parameters are as shown in Table 1.

THAI® is an in-situ controlled-combustion process that cracks, upgrades, and mobilizes heavy oil. Compressed air is injected into the reservoir after a pre-injection-heatingcycle (steam) brings the reservoir up to an appropriate temperature (90°C) for combustion to occur. The bitumen is then cracked leaving a coke zone that becomes the fuel for the process. In front of the coke zone is a mobilized and upgraded oil zone that is then produced by a horizontal well through gravity drainage. The THAI® process does not require gas or water as in Steam Assisted Gravity Drainage (SAGD) except in the pre-ignition start-up phase (Kendall, 2009).

Method

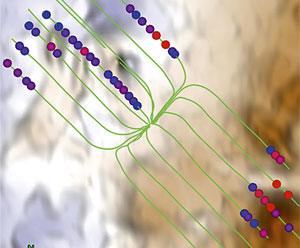

4D-3C seismic was utilized to monitor both the advancement of the THAI® front and caprock integrity. The purpose-shot time-lapse in 2011 utilized a digital 3C acquisition system with dense line spacing resulting in 15x15m bin sizes. This shoot will act as the first time-lapse 3C baseline, with future shoots to monitor combustion front development through time. A regional exploration 3D existed in the area (PP only-1995 vintage) that was reoriented to the new 2011 shoot geometry and pre-stack interpolated to match the tighter line spacing. This was done to have a baseline seismic survey (1995) that was shot before the reservoir was ever produced, to compare with the new 2011 seismic survey.

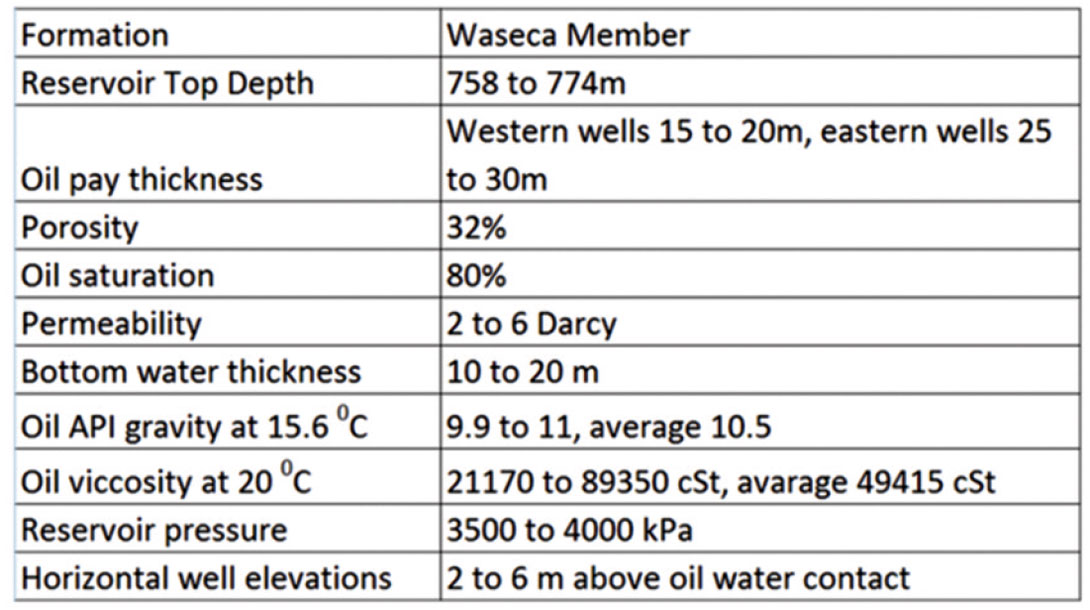

The parameters for the two shoots are shown in Table 2. Of note are the different sources, line layout (and orientation as well), in addition to being shot in different seasons.

This resulted in a pseudo-baseline survey that was shot before much of the primary production occurred. This allows us to not only assess the movement of the THAI® front, but also to assess the degree of primary depletion present in the reservoir due to secondary gas and the presence of CHOPS wormholes, a result of primary production.

Examples

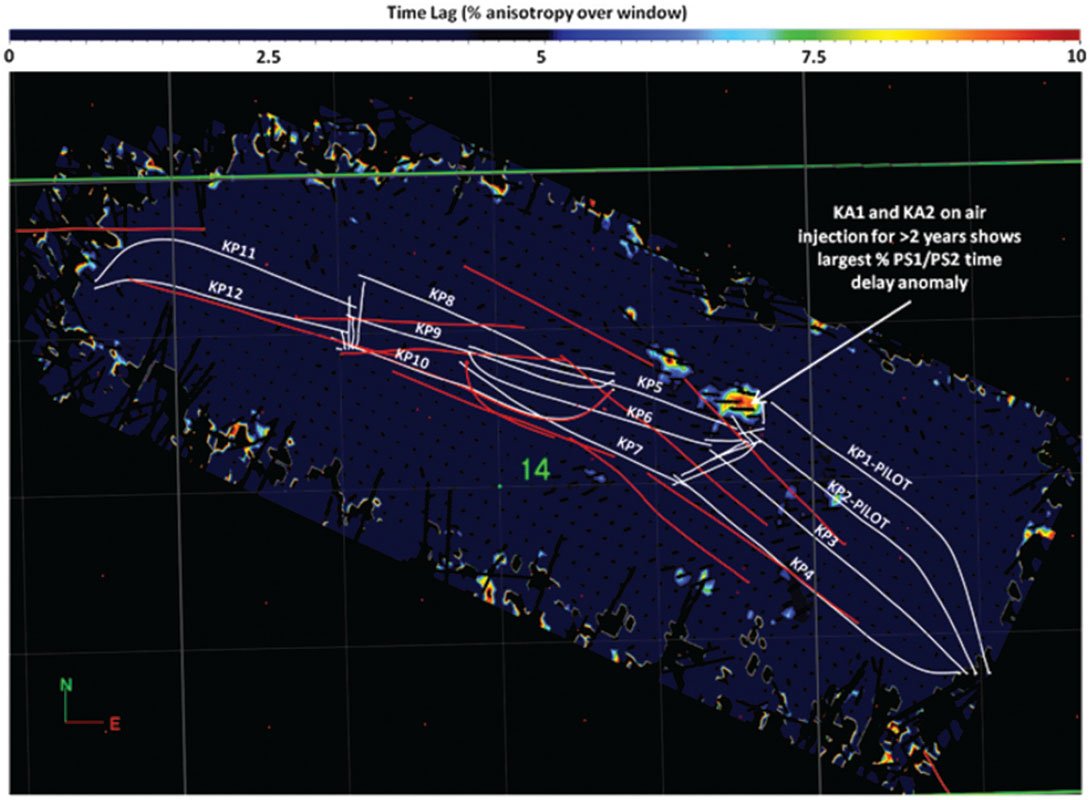

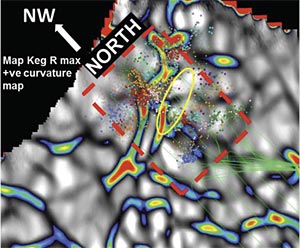

The results of the Kerrobert 4D PP analysis are shown in Figure 2. The 2011 Waseca base has been differenced from the 1995 Waseca base horizon to produce this simple time delay map. The time delays in this map are a result of velocity decrease in the Waseca reservoir from combustion heat (correlated to wellbore temperatures) and combustion gas presence. In addition to this, several anomalies exist at vertical wells and legacy primary production horizontals that are not associated with the THAI® process. Wormholes, a byproduct of sand production during CHOPS, and/or secondary gas from initial production has caused this time-lapse anomaly to occur as sand is produced and production drops the reservoir pressure (below the bubble point where gas comes out of solution).

Figure 3 shows the PS1/PS2 time delay with the PS1 direction referenced to true north overlaying the horizon as a vector (vector size scaled by time delay). When we look at the time delay (~7ms) as a percentage of the layer stripping window used (50ms), we get an idea of the percent anisotropy over the reservoir (Waseca layer). As shown in Figure 3 there is a large anomaly which shows 10% anisotropy over the window. In addition, this large PS time delay anomaly is located at the bottomhole location of the two air injectors in the field that have injected the largest volumes of air and have been implementing THAI® for the longest period in the field (KA/KP 1 and 2). These two air injectors and horizontal producers were the location of the THAI® pilot in this field.

Conclusions

4D PP seismic is used to monitor THAI® front growth and movement in the reservoir with good agreement between the seismic anomalies and temperature measurements from the reservoir. In addition, an unexpected response from primary production in the area is also visible on the 4D as a result of the presence of wormholes from CHOPS and secondary gas from initial production. These anomalies can be used in the future to constrain reservoirs with similar oil compositions and secondary gas to justify down spacing and constrain drainage areas in older fields.

PS splitting is used to constrain the area of stress change due to the THAI® in-situ combustion process. The largest shear wave anisotropy anomaly is present in the location of the largest amount of historical air injection. This leads to the inference that PS splitting attributes can detect stress effects in the reservoir and/or caprock caused by thermal recovery processes. These data can be used in the future as a constraint on reservoir simulation and for geomechanical analysis of the reservoir and caprock.

Acknowledgements

The authors would like to thank Petrobank Energy and Resources for the opportunity to present this work. In addition, we would like to thank Synterra Technologies for project management of our seismic shoot and Key Seismic for processing and insight into the data.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article