Stinking foul mess

Biodegraded

Our ultimate fate

There are numerous reasons why we are lucky to live in today’s world, but access to modern plumbing and sewage treatment has to be near the top of the list. Maybe things weren’t so bad when there weren’t many of us around – it is estimated that total global human population never exceeded 15 million prior to the invention of agriculture, so lots of room to pursue the call of nature - but living in a city today with high population densities would be intolerable were it not for sewage treatment technologies. Canada’s urban population density is ~1,550 per km2, Europe’s is 4,750 per km2, India’s is 15,700 per km2, and China’s is a staggering 29,000 people per km2 in its urban areas.

Let’s translate that into some hard numbers. There is a wide range of estimates out there for average daily human fecal production – Encyclopedia Britannica’s 3-8 oz. per day per adult on the low end, and as high as 2-4 lbs. from less reliable sources. However, the most common number I was able to find was that humans on average produce 1 oz. of feces per 12 lbs. of body weight, per day. That means, using the latest Calgary demographic stats and assuming the average child weighs 50 lbs. (parents know that babies punch above their weight class in this respect), and the average adult 150 lbs., that the city is producing ~860,000 lbs. of feces per day! Now you have to realise, 75% of that is water, but that water isn’t sparkling glacier fed H2O; it’s tangled up with 8% indigestible fibres, 8% dead bacteria (!), 4% fats, 4% salts, and 1% proteins. Imagine that stinking mess being deposited in our parks, streets, front lawns and back alleys, and I think you get what I’m talking about. And we aren’t even bringing urine into the discussion.

How do we deal with all that feces? This article will focus on modern sewage treatment technologies. The reality is that fecal matter is just one of many types of waste which we create and get rid of through our sewage systems. A modern sewage system is designed to separate out three main types contaminants – physical, chemical and biological – and output safe fluid waste also known as effluent, and solid waste also known as sludge.

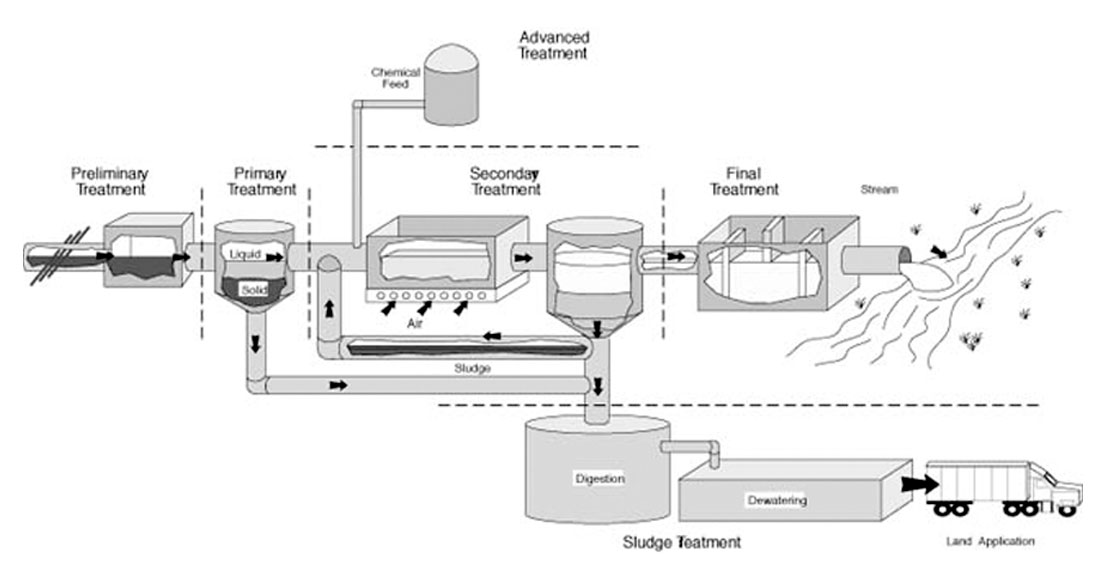

Municipal sewage systems usually involve a few centralized treatment plants, with a system of pipes delivering the liquid waste from the larger community to the plants. This is the case in Calgary, where sewage flows or is pumped to one of three wastewater treatment plants – Bonnybrook (Figure 1), Fish Creek, and Pine Creek. These three plants collectively process on average, 430 megalitres of wastewater per day! The City of Calgary has an excellent description of how its system works, and the link is provided below. The technology employed in Calgary is fairly typical and can be broken into four main stages – pre-treatment, primary, secondary and tertiary. Figure 2 illustrates in a simplified fashion the many steps involved in breaking down raw sewage into environmentally safe constituents.

Pre-treatment

The first step in pre-treatment is to remove larger physical objects (such as Lego, tennis balls, condoms – you name it) and grit, sand, glass, etc. Anything that could get stuck within the plant’s pipes and mechanisms needs to be removed, as well as larger particulates that compromise uniform flow rates and can damage pumps. This part of a treatment plant is sometimes referred to as the headworks. To remove the larger physical objects, large screens are raked through the sewage. Whatever they catch is either incinerated or taken to a landfill. After this the sewage flows through settling tanks at varying velocities designed to settle particulate material, which is also removed and disposed of.

In some plants the pre-treatment stage can include flow adjustment and fat & grease removal. Flow adjustment basically involves holding tanks that can accommodate fluctuations in flow due to seasonal factors, such as the recent flooding in Calgary, or other factors. The ability to hold large volumes of raw sewage also makes plant maintenance easier. If there are unusually large inflows of particular contaminants, for example the delivery by truck of large volumes of portable toilet or sewage tank fluids, then this part of the plant can be used to dilute and distribute the fluids appropriately. Fat and grease can be skimmed off the top of specially designed tanks with the help of clarifying agents, or can be frothed off the top with blowers. Usually though, fats and greases are dealt with later in the primary stage.

Primary Treatment

The goal in this stage is to separate the bulk of the solids from the fluid, as well as remove fats and greases if this hasn’t already been done. The primary treatment represents a fork in the process, with solids and liquids following different paths once separated at this stage. The sewage flows out of the headworks into large settling tanks, usually open air. Sludge settles to the bottom, where it is physically scraped out into hoppers that take it off to the sludge treatment process, described later on under tertiary treatment. Fats and greases rise to the top with the help of clarifying agents, and are skimmed off and removed; usually they are also taken to the anaerobic sludge treatment facility. Note that at this stage the process has involved only physical processes. The much cleaner fluids now exit the primary treatment stage and enter the secondary stage where largely biological processes are applied.

Secondary Treatment

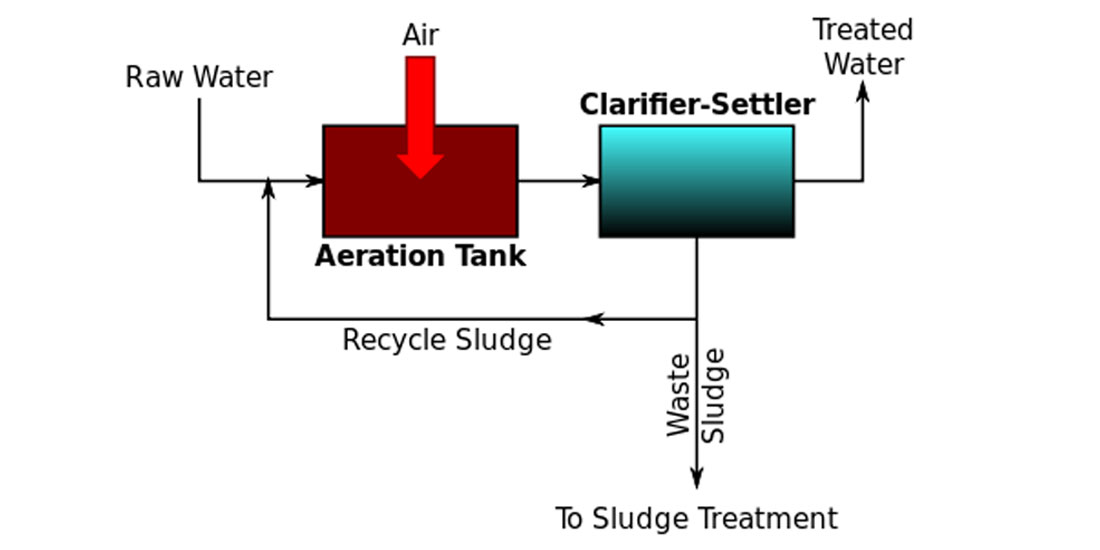

There are various secondary treatment methods used, but they all involve biota (bacteria and protozoa) breaking down biodegradable compounds, and binding less soluble materials into floc, that is larger clusters or conglomerations which can then be more easily removed. These biodegradation processes require oxygen, and there are variations in the way oxygen is introduced to the liquid. Smaller systems employ surface aeration; most of us will have seen tethered floating pumps at rural plants which circulate the fluid so it comes into contact with the air. Larger plants such as those in Calgary usually use what is called an activated sludge system, as this is more effective. Here, compressed air is injected into the bottom of the large tanks. The liquid sewage churns around in these tanks for around 7 hours, with the oxygen and microbe rich fluid basically stimulating an orgy of biodegradation. After this the “mixed liquor” – an interesting term – flows into secondary clarifiers, where it spends another ~7 hours.

In the secondary clarifiers the heavier organic solids, which are now forming coagulated lumps, sink to the bottom; most of this activated sludge is recycled back to the aeration bioreactor tanks (see Figure 3), but some exits the secondary treatment loop and joins the sludge from the primary treatment stage (see Figure 2) for sludge treatment, described below. Note that any remaining fats and other types of scum are skimmed off here and dealt with in the same fashion as the fat and scum in the primary treatment stage. The essentially clear effluent on the top of the secondary clarifier flows out to the UV disinfection facility.

Tertiary Treatment

UV Treatment

After leaving the secondary clarifiers, all that remains is a disinfection stage before the fluids are ready for discharge back into the environment, i.e. a river, lake or ocean. There are a variety of ways disinfection can be achieved, but the use of chlorine or ozone is falling out of favour due to environmental reasons (chlorine) or costliness (ozone).

Many modern facilities, including Calgary’s, now use UV technology. The fluids should now be clear, and in fact cloudiness can diminish the effectiveness of UV exposure, thus systems using UV disinfection require very stringent primary and tertiary stages. The UV light genetically / molecularly damages any remaining pathogens, thus rendering the water entirely safe.

Sludge Processing

Ah yes, back to the sludge – we haven’t forgotten you, you stinky, slimy excremental ooze. The sludge and scum collected in various earlier stages heads to an anaerobic digester for about a month, where complex organic materials are broken down by bacteria that thrive in environments without oxygen. The sludge is continuously mixed and kept at about 35C, as this accelerates the bacterial action. The output of this process is mainly water, methane, and CO2. The methane in some operations can be used as an energy source, the water is disinfected and discharged, and the remaining sludge, now largely safe, is either taken to a land fill or disposed of in some other way. In Calgary it is taken to the Shepard Lagoons, where it settles further. The resulting water is piped back as an input to the headworks at the treatment plants, while the settled solids are packaged into farm fertiliser as part of a program called Calgro.

Sewage treatment is a huge field, and there are many systems used which I haven’t mentioned, and many emerging, more environmentally friendly technologies. But hopefully I’ve given you a basic understanding of a nasty business that goes on day in and day out almost completely without our knowledge, and yet has a tremendously positive impact on our quality of life.

One thing that has struck me as I researched and wrote this article is how similar the philosophies used within an amplitude friendly seismic processing flow are to sewage treatment. If you think of our desired seismic signal as the water in the sewage, then the analogy is quite apt. In processing we iterate over and over to remove ever more subtle noise from the signal, just as a wastewater treatment plant keeps reintroducing fluids back to earlier in the flow as the solids and contaminants are progressively separated and removed.

Writing this article is one of the last things I have to do before heading off to Singapore for three weeks. Singapore is to my knowledge the only country to have implemented large scale use of treated wastewater within their domestic potable water supply. This means that my faith in science and technology is going to be put to the test, every time I lift a glass of water to my lips!

Key Search Words: Sewage, digester, activated sludge

References

Encyclopedia Britannica. (2013). Feces. Retrieved July 29, 2013, from Encyclopedia Britannica: http://www.britannica.com/EBchecked/topic/203293/feces

Mancl, K. (2013). Wastewater Treatment Principles and Regulations. Retrieved August 3, 2013, from Ohio State University: http://ohioline.osu.edu/aex-fact/0768.html

Marsh, D. (2011, March). Doing it right with data. Retrieved August 3, 2013, from Treatment Plant Operator: http://www.tpomag.com/editorial/2011/03/doing_it_with_data

The City of Calgary. (2013). Wastewater Treatment. Retrieved August 3, 2013, from The City of Calgary: http://www.calgary.ca/UEP/Water/Pages/Water-and-wastewater-systems/Wastewater-system/Wastewater-Treatment.aspx

Wikimedia Foundation, Inc. (2013, July 26). Sewage treatment. Retrieved August 3, 2013, from Wikipedia: http://en.wikipedia.org/wiki/Sewage_treatment

Share This Column