I get feedback on these Science Break articles, something I really enjoy. On the topic of war, encryption and crosswords, Jim Laing drew my attention to a WWII story involving a Surrey, England headmaster who was a regular crossword author. English intelligence noticed a suspiciously high number of their “secret” code words were showing up as answers in his crossword puzzles. Was he a German spy, passing on secret information in the most cunning of ways? Here are a couple of links with more on this story.

http://en.wikipedia.org/wiki/Normandy_landings#Cross word_panic_of_1944

Penny Colton pointed out my curious spelling of “magnetotron” versus the more commonly used “magnetron”. I kick myself over that one, as I’ve always spelled it as “magnetron”! At some point during my research I came across the “magnetotron” spelling and switched over to it, assuming it was more correct without too much thought. “Magnetron” is definitely the more common spelling, and the one I should have stuck with. I think it’s a British versus American spelling thing.

Pat McKenny brought up issues related to fluorescent lights, specifically compact fluorescent lamps (CFL’s). First, as with all fluorescent lighting devices, there are concerns over the environmental impact of the mercury used in them. We wondered how the ballast is contained in CFL’s (they are electronic versus the traditional magnetic, and thus much smaller, giving quicker starts and far less flicker). Pat also mentioned that recent studies are showing that the UV light emitted by CFL’s can be problematic for people with sensitive skin, especially when the CFL is positioned within 1m of the skin, for example above your bathroom mirror. For safe, low cost, environmentally friendly lighting that fits standard sockets, Pat is a proponent of LED lighting, and even has a line on where to buy it, cheap!

Cogeneration

If there’s anything that can help resuscitate the Canadian conventional gas industry, it’s cogeneration power plants, or cogen plants as they are often called. I thought I knew what cogeneration was, but I was quite wrong. I thought it referred to electric power generation plants that could be fueled by either gas, coal, or oil, but my friend John Behr set me straight, as he often does. In fact, more than once he’s given me the idea for a Science Break topic; we have a sort of dog and master relationship, where John throws me an idea and I chase it.

The term cogeneration has been around for a long time, and refers to using the waste heat created during power generation for some secondary use. This has been given the acronym CHP, or combined heat and power. All of us here in Canada are beneficiaries of a very common CHP application in our cars: gasoline drives the primary power generation, and then the excess heat produced is partly used to warm the passenger compartment. Under the general cogeneration heading are a number of specific applications, each with a catchy acronym.

For example, the hot water output from a power plant’s steam-driven turbines could provide heat to a nearby community. This is called combined heat and power district heating (CHPDH).

CCHP – which stands for combined cooling, heating and power, and is also referred to as trigeneration, or polygeneration – applies to plants which are designed to output power, heating and cooling. When this is done within a single facility it is usually referred to as BCHP – building cooling, heating and power – and is a common way for large scale industrial operations such as pulp and paper mills to squeeze more utility out of their power. By generating their own electrical power and using the otherwise discarded heat to both heat the facilities (or to do other things) and provide cooling (for aircon or other purposes), they get way more bang for their buck.

Cogeneration is really an effort to make more efficient thermodynamic use of an energy source, something that is becoming more and more important as we anticipate the inevitable decline in cheap energy supplies, not to mention competition in industry to minimise cost structures. Which brings us to the prospect of a reliable long term supply of natural gas here in North America, due to the advent of shale gas production. So far the increase in supply has meant low gas prices and misery for the Calgary oil patch (and us geophysicists), but Adam Smith would surely predict the advent of some new demand to match the increase in supply. That is where CCGT comes in.

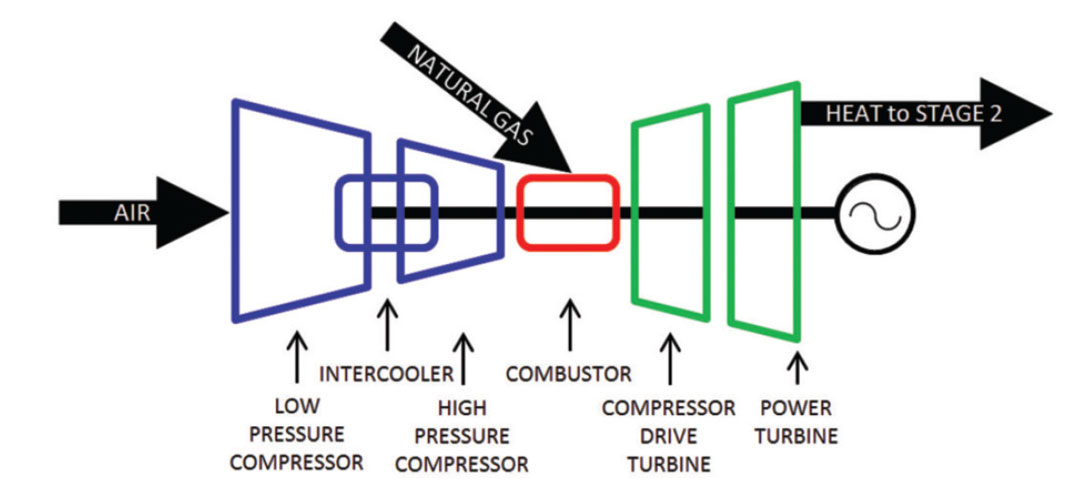

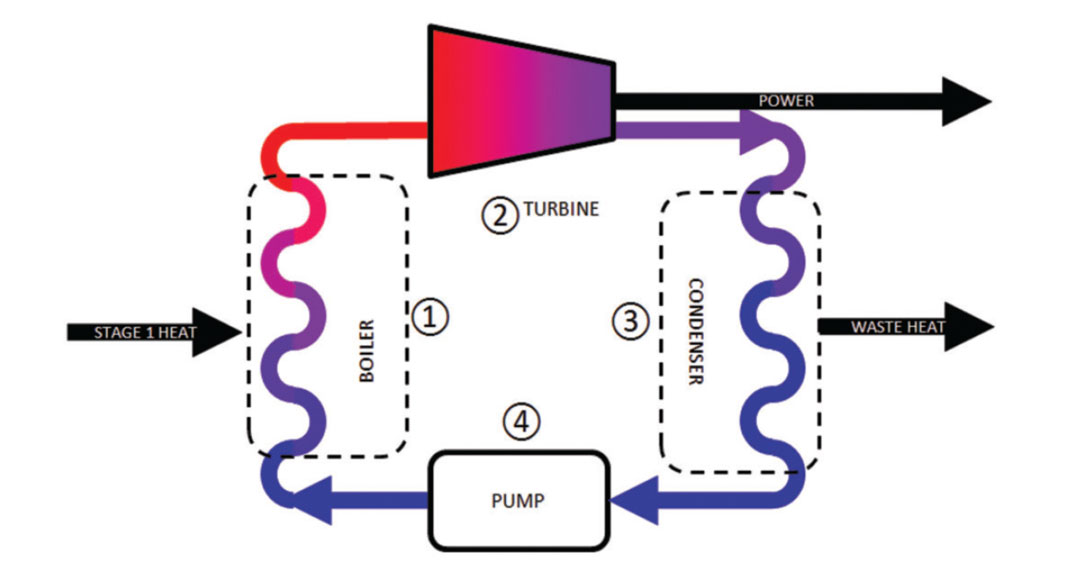

“CCGT (closed cycle gas turbine) is a special case of power cogeneration, and can achieve ~60% efficiency for electrical power generation; that's really high, almost twice the amount of a single cycle.” (Behr, J., personal communication, April 11, 2013) Most new power plants being built use CCGT, with a two stage process. The first stage involves a Brayton cycle gas turbine (Figure 1), the second stage a Rankine cycle steam turbine (Figure 3).

Brayton engines are easily understood, with only three main components, and were first seen in the 1800’s as steam engines. Today the same basic concepts are applied to turbines, such as jet engines, or in this case, gas turbines. First input air is compressed; second it is mixed with natural gas and combusted, producing a high-pressure, high-temperature flow of gas, primarily air; third, this air is directed to flow through an expansion turbine which it rotates as it rushes through and exits at a much lower exhaust pressure. The turbine’s shaft drives the electricity generation and the input air compression. The energy produced by Brayton cycle turbines is directly proportional to the difference in temperature between the input air and the air after combustion; because of this, advances in the technology have focused on turbine systems that can get the air much hotter, and turbine components that can tolerate higher and higher input temperatures. It also explains the intercooler seen in Figure 1. Note that the turbine has the same basic steps as a piston-driven internal combustion engine – induction, compression, combustion, expansion – but it is elegantly rotary without the herky-jerky piston motion.

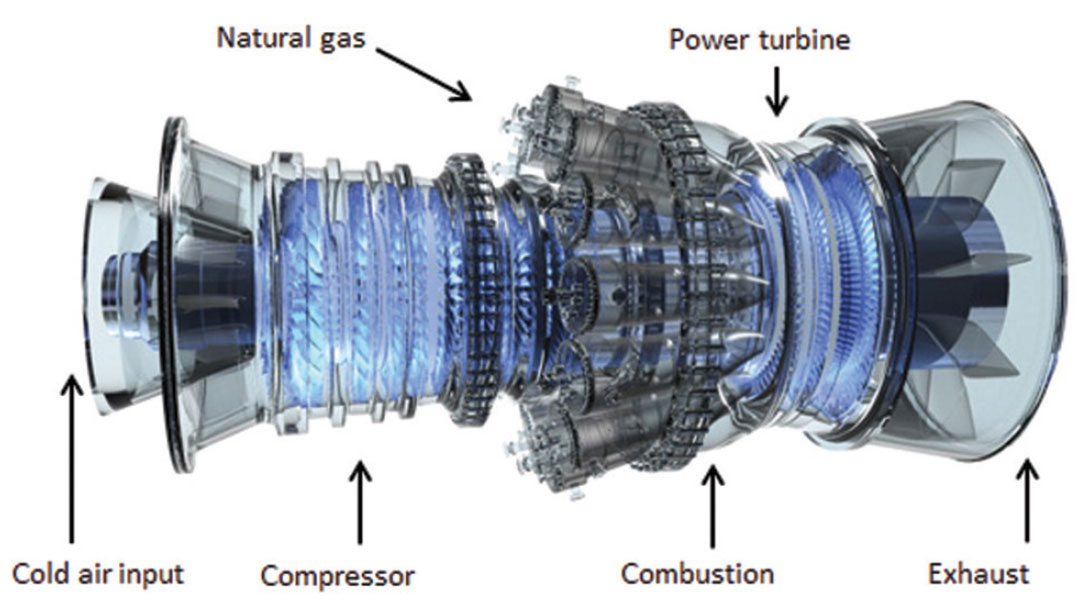

Incidentally, I sometimes play tennis with a guy whose company sources out decommissioned large jet engines, and sells them to be repurposed for electricity generation. I like to think of that as being similar to the old days where a retired race horse would enter a second career perhaps in a grain mill, or in front of a cart; a more pleasant fate than the scrap mill or glue factory. While used jet engines make excellent power generators, those that are built for stationary use are obviously superior, especially when they are purposely designed for use in a high tech CCGT power plant. But jet engines and power generation turbines are remarkably similar. Figure 2 is an image of a modern General Electric 7FA gas turbine used for power generation, but it looks very much like a jet engine.

Upon exiting the gas turbine, the hot air enters the second stage Rankine cycle steam turbine, where it is used to vaporise compressed water within a heat exchange unit / evaporator (step 1 in Figure 3). The high-pressure vapour then flows through an expansion turbine similar to the one used in stage 1. This turbine’s shaft generates electricity, and drives the water compression later in the cycle. Upon exiting the turbine, the vapour passes through a condenser unit where much of its heat is extracted and it returns to a liquid state. The water then flows to the last step where it is compressed, ready to start the cycle over again. Note that the heat extracted in step 3 can be used to heat the plant or for other purposes. It is my understanding that some power plants are now cascading more than one steam turbine cycle, with each successive cycle operating at a lower pressure. These types of strategies can actually push the thermodynamic efficiency of such plants up to over 80%.

“Practically, you can only use natural gas to power CCGT because other fuels like oil and coal have too many impurities in them. Corrosion and ash deposition reduces the efficiency and life of the turbines. The energy equivalence of gas to oil is 6000 ft3 to 1 bbl. of oil; when used in power generation it would be closer to 3000 ft3 to 1 bbl. Thus with CCGT, natural gas' value based on "energy density" almost doubles when compared to oil or coal.” (Behr, J., personal communication, April 11, 2013) Note that synthetic gas produced from coal is perfectly usable within a CCGT plant.

So given the abundance of new domestic natural gas supplies, the economic advantages of producing electricity in CCGT plants, and the environmentally friendly aspects of natural gas, it is likely that over time, as older plants are retired, North American electricity generation will shift over to CCGT plants. In addition to restoring the supply-demand balance for natural gas, the availability of cheaper electricity should help restore the competitiveness of the North American manufacturing sector. (It must be spring, as I’m filled with optimism!)

Key search words: Cogeneration, gas turbine, combined cycle

References

Energy Solutions Center Inc., DG Consortium 2012. (2004). Gas Turbines. Retrieved April 26, 2013, from Understanding CHP: http://www.understandingchp.com/appguide/chapters/chap4/4-3_gas_turbines.htm

General Electric Company. (2009, October 27). GE’s revved-up 7FA natural gas turbine takes a bow. Retrieved April 26, 2013, from GE Reports: http://www.gereports.com/ges-revved-up-7fa-natural-gas-turbine-takes-a-bow/

Wikimedia Foundation, Inc. (2013, April 7). Brayton cycle. Retrieved April 26, 2013, from Wikipedia: http://en.wikipedia.org/wiki/Brayton_cycle

Wikimedia Foundation, Inc. (2013, April 24). Cogeneration. Retrieved April 26, 2013, from Wikipedia: http://en.wikipedia.org/wiki/Cogeneration

Wikimedia Foundation, Inc. (2013, April 10). Combined cycle. Retrieved April 26, 2013, from Wikipedia: http://en.wikipedia.org/wiki/Combined_cycle

Wikimedia Foundation, Inc. (2013, April 25). Gas turbine. Retrieved April 26, 2013, from Wikipedia: http://en.wikipedia.org/wiki/Gas_turbine

Wikimedia Foundation, Inc. (2013, April 11). Rankine cycle. Retrieved April 26, 2013, from Wikipedia: http://en.wikipedia.org/wiki/Rankine_cycle

Wikimedia Foundation, Inc. (2013, February 27). Turboexpander. Retrieved April 26, 2013, from Wikipedia: http://en.wikipedia.org/wiki/Expansion_turbine

Share This Column