In Land Seismic operations there is a strong industry drive to continually improve quality and productivity, to meet the ever increasing demands for cost-effective high-density and wide-azimuth recording. There is also a shift towards a point-source, point-receiver acquisition model where the aim is to reduce the size of conventional source and receiver arrays.

The goal here is geophysical. Source and receiver arrays are used to improve the signal-to-noise ratio of the recorded data with the summed energy of multiple sources and the summed response of receiver arrays. However, this rather crude method of improving signal amplitude has some geophysical shortcomings and causes problems for processing with effects such as intra-array statics and residual normal-moveout across the array.

For the receiver array, the evolution of seismic recording equipment lets us deploy more channels and reduce the array size. Single digital geophone units can also be deployed as point-receivers. The real challenge lies in reducing the source array size – particularly for vibroseis operations.

The solution to source array size builds on existing CGGVeritas technology. This is the patented High- Productivity Vibroseis Acquisition (HPVA) technique which has enjoyed considerable success in North Africa and the Middle East. It has achieved recent productivity records of over 200 source positions per hour.

The reason why HPVA has been so successful is because it provides improvement in productivity while enhancing image quality. The technique is based on slip-sweep vibrator operations where several vibroseis source arrays (typically a fleet of 3-4 vibrators) overlap their source sweeps and hence speed up operations. HPVA refines the slip-sweep technique by removing the harmonic interference between the concurrent vibrator fleet sweeps. This allows three or more fleets to be deployed and overlap their sweeps recording high-quality high-density wide-azimuth data with higher productivity.

So what is going to bring the next big leap in quality and productivity and solve the source array problem?

The answer lies in CGGVeritas’ V1 single-vibrator acquisition technique which extends the HPVA technology to single vibrators, so that, for instance, 12 fleets of 1 vibrator are deployed instead of 3 fleets of 4.

To achieve this ambitious goal, certain technical and operational hurdles must be overcome.

To maintain source power and signal amplitude, the sweep length is increased and the density of the shot point grid is also increased. This will increase the fold of the recorded dataset giving greater stacking power (and hence signal amplitude) during the processing.

With the deployment of a large number of vibrator sources a robust and efficient operation is the key to success. A new concept in vibrator fleet management has therefore been introduced to ensure this. The vibrators move independently on their designated shot lines and are automatically allocated slots in a shooting schedule. This new acquisition concept makes for very efficient and flexible single vibrator operations.

The final challenge is recording the dataset. With long sweeps, small slip-times and multiple sources firing on a complex schedule, a continuous stream of data flows from the receivers. For our 12 vibrator example, up to 8 vibrators can be sweeping concurrently whilst the other 4 are moving to the next shot points and preparing to fire. The data therefore has to be recorded continuously along with accurately synchronised source information and shooting “timestamps”. Application of already proven HPVA technology allows the seismic data to be recovered from this mass of information without degradation of the signal due to harmonic interference between records from overlapping sweeps.

Now that the technical hurdles have been resolved, exactly what improvements in productivity and data quality can V1 single-vibrator acquisition deliver? This partly depends on what is required for a specific survey. The actual productivity of V1 will be determined by required record length, sweep length, displacement time and the resulting number of vibrators that can be deployed.

Actual acquisition statistics from field tests of V1 single vibrator acquisition during a 3-fleet survey show a dramatic 250% increase in productivity in terms of shot-points acquired for 12 vibrators.

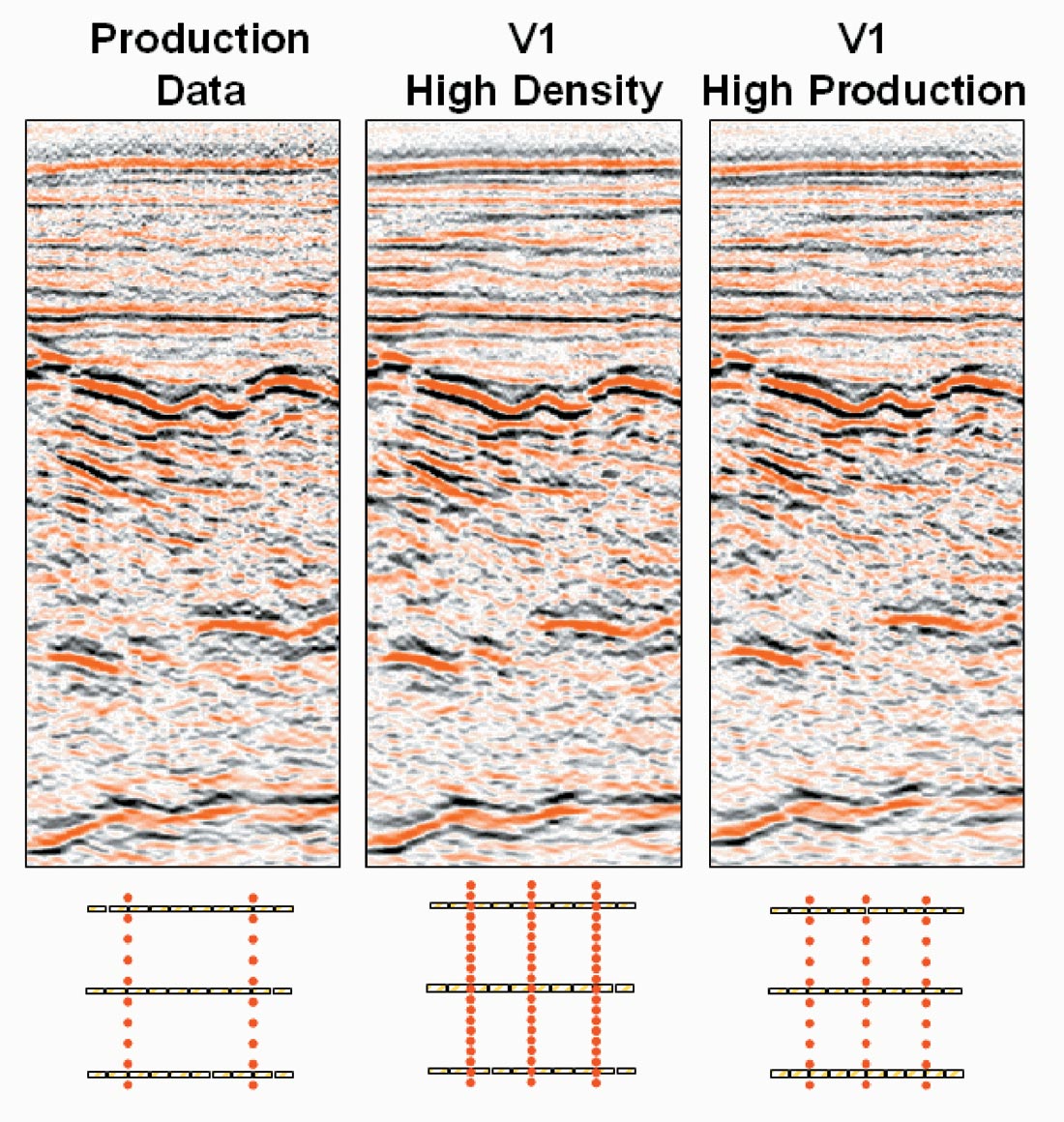

This additional productivity can be used to acquire a dense, high-fold dataset for a similar km2 / hr production rate. This quadruples the shot point density and the results shown in the Figure 1 “High Density” panel indicate a marked improvement in resolution and signal content in the stack section.

If, on the other hand, the priority is the production rate, V1 provides scalable options to meet both turnaround time and quality objectives. In the Figure 1 “High Production” panel, productivity was increased 60% whilst increasing the density of the shot-grid sufficiently to improve the image quality.

The limited power of single vibrator sources is fully compensated by an increased density of shot points. This does not limit data quality or production rates since the additional production capacity is large enough to ensure that both of these criteria are more than met, as demonstrated by the field tests.

CGGVeritas has previously set production records with our HPVA crews using three fleets of vibrators to achieve 240 shot points per hour – an improvement of 50% over standard vibroseis techniques. In the V1 tests completed in 2006 a new record of 590 shot points per hour was set – an incredible 250% increase in productivity with no increase in the amount of equipment and crew effort.

Whatever the survey objective, the benefits of CGGVeritas’ V1 technology (patent pending) are clear. With V1 a step change in subsurface illumination is available through highly productive high-density, high-resolution, wide-azimuth land seismic acquisition. In addition undesirable source array effects have been removed from the data by using a point-source, resulting in a dataset more suitable for sensitive applications such as high-resolution imaging and reservoir characterisation.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article