Introduction

What’s going on? Are these trends sustainable? What is the role of a geoscientist in this crazy new world?

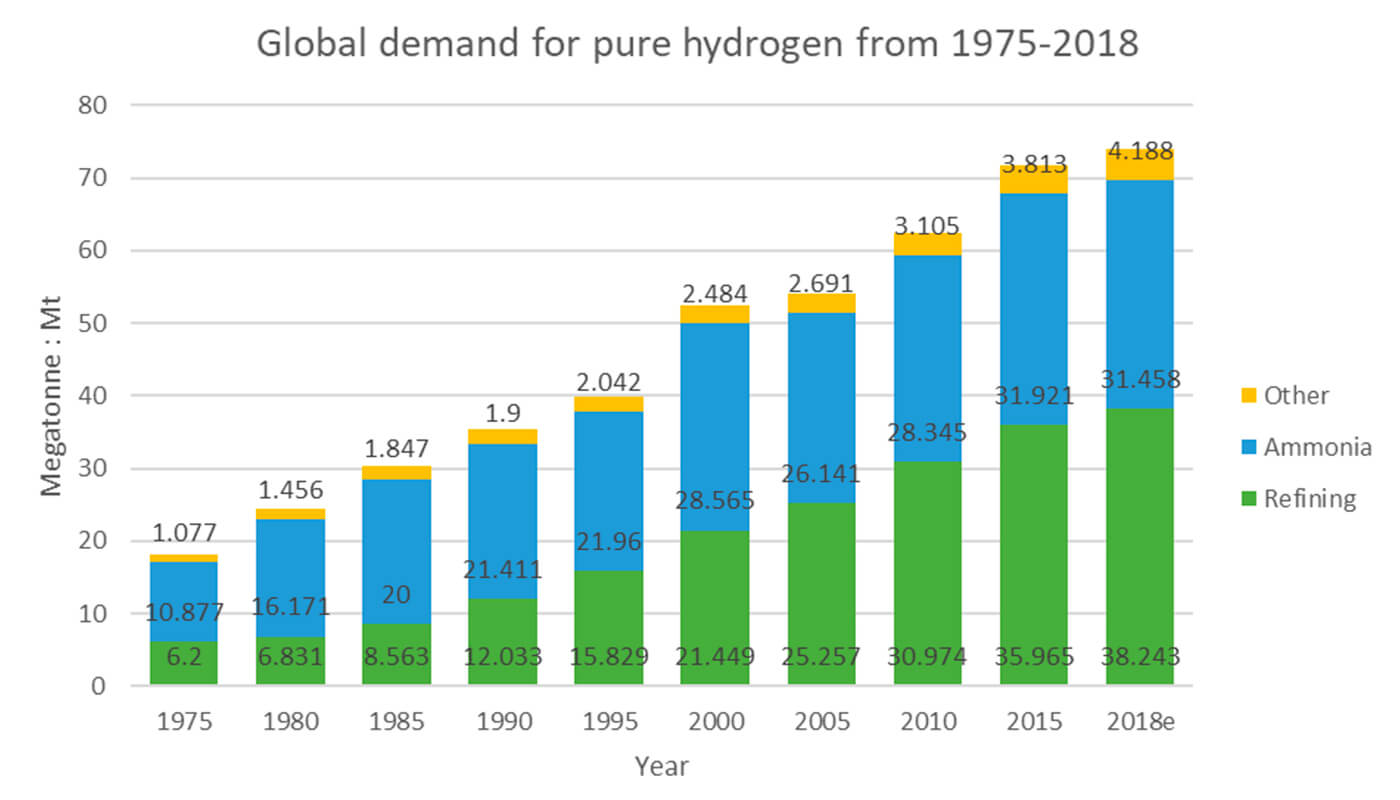

There are many different viewpoints on where we see the future of energy heading in the coming years and decades. Nowadays, there’s no question that renewable energy has gone from being simply a buzzword, into something that we see actively being turned into a reality over the globe. Such an example of a renewable energy source that has become the center of attention is hydrogen (H2). Based on a 2019 technical report commissioned by Japan for the G20 and conducted by the International Energy Agency (IEA), global demand for hydrogen has gone up by four times since 1975 when global demand sat at 18.2 Megatonnes (Mt), in comparison to the demand in 2018 (most recent year with data) of 73.9Mt; see Figure 1.

For the most part today, this hydrogen is used in oil refining and ammonia production, with innovation being geared to make significant breakthroughs in the transportation, power generation, and various other industries. Many governments across the world are greenlighting projects to expand on hydrogen research and infrastructure, with there being “around 50 targets, mandates and policy incentives in place today that directly support hydrogen, with the majority focused on transport” (IEA, 2019). Even Canada has the ability to take charge here as “government officials and analysts believe Canada has the building blocks to develop low or zero-carbon hydrogen through a variety of tools, including renewable energy. In the case of natural gas, carbon-capture technology could be used to produce low-carbon hydrogen” (Bakx and Seksus, 2020). However, as the IEA (2019) mentions, all of this comes with a pretty hefty carbon price tag of 830 Mt, which is roughly equal to the annual CO2 emissions of the United Kingdom and Indonesia combined. So one might ask, what is the point of even producing all of this hydrogen if we are still creating so much pollution? Isn’t the whole point of switching to renewables to bring emissions down?

Well, if we intend to meet our Paris Climate Agreement (2015) obligations, we must actively be “pursuing efforts to limit the temperature increase to 1.5°C above pre-industrial levels, recognizing that this would significantly reduce the risks and impacts of climate change”. A similar message from the Government of Alberta, “Deploying hydrogen […] is key to Canada’s ability to meet GHG reduction targets under the Paris Accord.” (Government of Alberta, 2020). As the IEA’s analyses show, the cost of renewable energy sources such as solar and wind is decreasing as it becomes more prevalent in society, meaning the ability to produce hydrogen without fossil fuels, is a very realistic goal that is well within our reach. Now, with that being said, the approach taken here must also consider a lot of logistical and technical factors such as: the production method and the source of hydrogen; conversion, transportation, and storage; and emissions at all stages from start to finish. With hydrogen development being geared toward more domestic uses such as cars, buses, and home uses, and not just solely for the industrial purposes as mentioned earlier, the conversation then starts to include your average citizen as well.

For me it has approximately been a year since I first started actively researching about hydrogen when I heard about its potential to be used as a “zero-emissions” source of energy. And since then, I have been hearing about hydrogen everywhere [Baader-Meinhof Phenomenon]. Whether it was at school, over a coffee, at a networking event, and as I’m sure most of you would agree, on LinkedIn. As I said earlier, there are many questions that arise when discussing hydrogen, and with that, just as many people ready to give their two cents on what they think the future of hydrogen looks like. Well, this is my attempt at trying to provide a clearer overview, and more concise picture on some of the major factors and concerns surrounding hydrogen energy, and questions we should be asking ourselves and others to ensure a secure energy present, and future.

The Hydrogen Colour Wheel

As a rookie, hearing about hydrogen being associated with some weirdly put together “colour spectrum” really threw me off at first when learning about it, only to later find out that no such “spectrum” existed. In the hydrogen world, these colours are used to describe the method and source of production of said hydrogen; and all of them vary in costs and emissions. Generally speaking, I will be talking about the three main types of hydrogen: grey (in some literature referred to as black), blue, and green. And to leave no stone unturned, it is also worth mentioning brown hydrogen which uses coal instead of natural gas and gets its recognition from China’s increasing reliance on coal. Although it accounts for 23% of the 70Mt of hydrogen produced annually (IEA, 2019), brown hydrogen is generally lumped together with grey.

Grey Hydrogen

This is the most abundant type of hydrogen produced, making up approximately 76% of global hydrogen production (IEA, 2019). Different (and relatively older) sources such as Liu et al. (2010) use 95% as the amount of grey hydrogen produced via natural gases by the petroleum, ammonia, and methanol industries. Grey hydrogen is produced from fossil fuels such as natural gases like methane (CH4), although this production can also happen using fuels such as coal, gasoline, and propane as well. Of the aforementioned 76% hydrogen production, Canada produces 8,200 tH2/day resulting in emissions of 9kgCO2/kgH2 (Layzell et al., 2020). One of the most popular processes by which this is done is termed: Steam-methane reformation (SMR). The United States Department of Energy (2020) explains this process as the reaction of extremely high temperature steam (700°C–1,000°C) with methane and a catalyst under 3-25 bars of pressure to produce hydrogen [Eqn. 1]; carbon monoxide (CO) is also produced as a by-product.

Steam-methane reforming reaction

Water is then reacted with the carbon monoxide in a “water-gas shift reaction” [Eqn. 2]. In this water-gas shift reaction, water and carbon monoxide are reacted with a catalyst (similar to SMR), which produces carbon dioxide and more hydrogen. By isolating the hydrogen through the removal of carbon dioxide and other impurities via a process called “pressure-swing adsorption”, you are left with relatively pure hydrogen.

Water-gas shift reaction

Now the obvious reason why grey hydrogen is the most used type of hydrogen by the energy industry is because it is the cheapest to produce, sitting at approximately 0.9-3.2USD/kg (IEA, 2019). As the old adage goes, “If it ain’t broke, don’t fix it”, and well to put it bluntly, aside from the cyclical ups and downs, this philosophy has worked for most of the private energy sector.

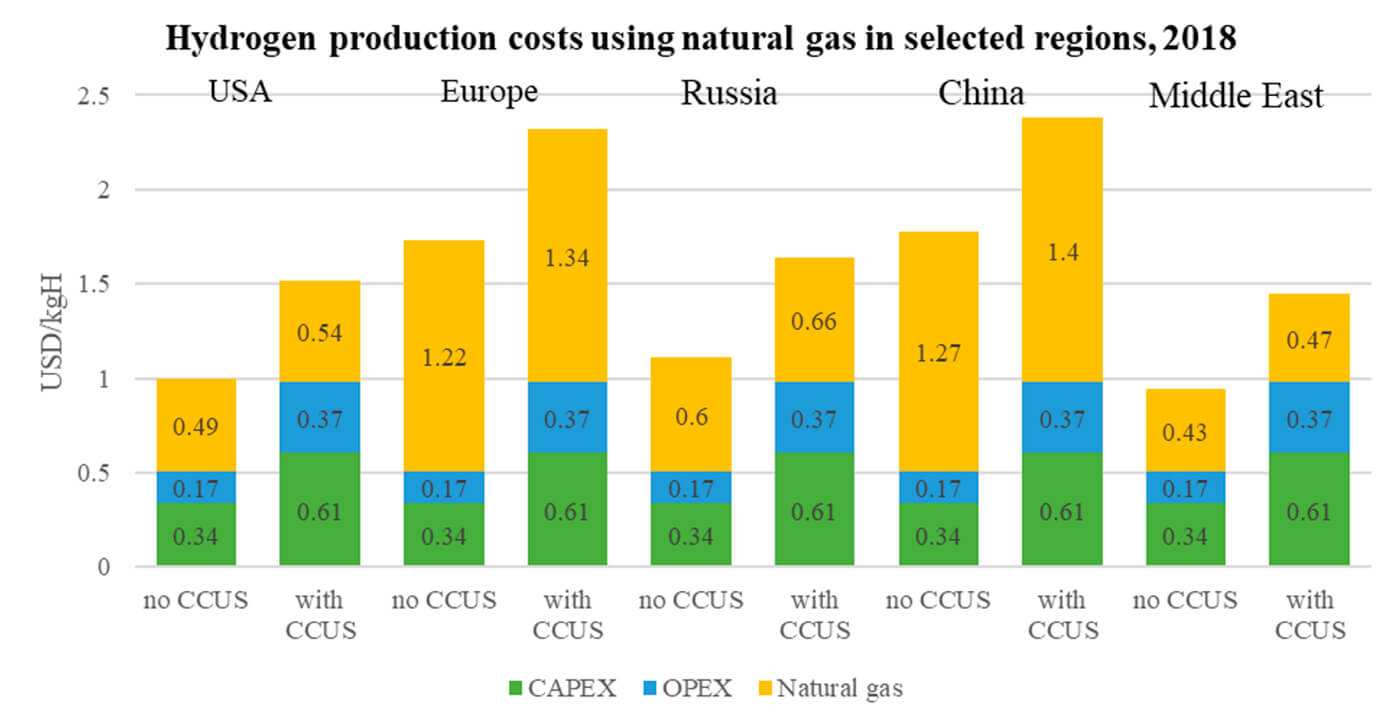

A commonality between grey and blue is that they both use natural gas, except grey hydrogen production does not use capture carbon, and instead emits that carbon into the atmosphere, whereas the blue hydrogen process captures and stores the carbon. Which is why typically blue hydrogen is met with resistance from a cost perspective but is preferred over grey from an environmental perspective. This is where the issue arises, as one can look at this from one of two lenses. Figure 2 does a great job showing a comparison for the costs associated with hydrogen production using natural gas with and without the use of carbon capture, utilization and storage (CCUS). In other words, this figure is able to show a cost comparison for the production of grey versus blue hydrogen.

There are some very interesting trends to notice in this graph: Having relatively low gas prices in North America, Russia, and the Middle East helps to lower hydrogen production costs; this can be compared to China which is one of the biggest importers of natural gas in the world, resulting in higher hydrogen production costs. This is why regional considerations must be taken when assessing for hydrogen strategies, because what may work for one country (‘source of hydrogen’ factor) may be expensive for the other (in this case China).

Blue Hydrogen

Typically speaking the cost associated with producing blue hydrogen is higher than that of grey, because now the component of carbon capture must be taken into consideration and paid for. The cost range associated with the production of blue hydrogen according to the IEA (2019) sits at around 1.5-2.9 USD/kg. Canada is considered to be one of the cheapest places in the world to produce hydrogen with Alberta being able to produce blue hydrogen for 1.14-1.52 USD/kgH2 (Layzell et al., 2020). This leads to 2-3kgCO2/kg H2 as lifetime emissions from hydrogen made from natural gas. In terms of greenhouse gas (GHG) efficiency with blue hydrogen, this is something that depends on how the hydrogen itself is used and can range from 90% all the way down to 32% efficiency (Layzell et al., 2020). Grey and blue hydrogen follow essentially the same steps for production, using the SMR process to produce four molecules of H2 per reaction however the difference is the presence of some sort of carbon capture system for blue hydrogen. Alberta is a prime example of a region that already “has existing hydrogen and carbon dioxide transportation and sequestration infrastructure” (Government of Alberta, 2020). A landscape where potentially hundreds of millions of dollars will be saved mitigating the main drawback to blue hydrogen which is its cost.

Green Hydrogen

Green hydrogen is produced through what is considered the cleanest method of the three; by using renewable energy to produce hydrogen through the electrolysis of water, i.e., the splitting of a water molecule into its constituents oxygen (O2) and hydrogen (H2). This renewable energy could be sourced from solar, wind, hydroelectricity, geothermal, biomass, etc. Earlier I had mentioned Alberta as an example of a Canadian blue hydrogen producer, well for green hydrogen we have Quebec setting the national example. With Quebec’s hydropower capabilities they are able to produce green hydrogen using their hydroelectrical infrastructure at a rate of 1.9-3.8USD/kgH2 (Layzell et al., 2020). There are three different types of electrolysis processes: alkaline electrolysis, proton exchange membrane (PEM) electrolysis, and solid oxide electrolysis cells (SOECs) (IEA, 2019). The term “clean” is used to describe green hydrogen, which in a sense is true since there are no emissions created during the actual production, but when we look at the lifecycle emissions, they “range from 0.8 (wind) to 3.4 (solar) kgCO2/kg H2” (Layzell et al., 2020). As it is for blue hydrogen, the draw back for green hydrogen is its cost, which ends up being higher.

Transportation

So now that the hydrogen has been produced, how do you get it from point A to B? In some instances, it’s just more economically feasible to build your hydrogen production next to where it is needed, that way you don’t have to deal with transportation costs; this is what is called, “distributed production” (United States Department of Energy, 2020). This works for industrial applications such as oil refinement or ammonia production where the hydrogen is generally produced and used on site. And since right now, the relative demand of hydrogen is low, this method of production is okay, but as the demand for hydrogen increases, then the move must be made to invest into a large-scale “centralized production” model (United States Department of Energy, 2020). Leading into a hydrogen transition is eventually going to require the large-scale movement and subsequent storage of hydrogen, and “to move any gas economically, it needs to be compressed” (Martin, 2020). Without getting too deep into the thermodynamics of it, hydrogen is extremely energy dense, in fact the IEA (2019) reports that it is approximately 3 times more energy dense per unit mass compared to natural gas. However, as great as that is, it does not have an impact on how the gas is compressed, since the mechanical energy (work) required to work the compressor has a linear relation to the moles of gas being compressed; in other words, the mass or volume does not matter (Martin, 2020). Furthermore, the density of natural gas is approximately 8.5 times denser than hydrogen, meaning it is harder to compress hydrogen, leading to more work needed to operate your current compressor. Once the hydrogen is compressed, the next step would be to ship it via pipeline. As mentioned earlier, when it comes to mitigating all the different factors, cost is usually the biggest limiting factor. If infrastructure exists, why not utilize it, or at least update/retrofit it so that you can utilize it. Trying to send another gas that has its own inherent properties down a natural gas pipeline leaves lots of room for potential problems. One of those problems is called “hydrogen embrittlement”. This is the phenomenon where essentially hydrogen diffuses through and reacts with the metal of the pipe, resulting in its weakening (Liu, 2010). The Northern Gas Networks in the UK commissioned the H21 Leeds City Gate Project for “determining the feasibility, from both a technical and economic viewpoint, of converting the existing natural gas network in Leeds, one of the largest UK cities, to 100% hydrogen”(Northern Gas Networks, 2016). Leeds, and the UK as a whole have been undergoing the Iron Mains Replacement Programme (IMRP) which is due to be completed by 2036. What was a scheduled change that was bound to happen, ended up bringing the added benefit of making sure the UK has the infrastructure to transport 100% hydrogen when it is able to do so. What we should take from this is that it is possible to set up infrastructure for hydrogen on a large scale.

Storage

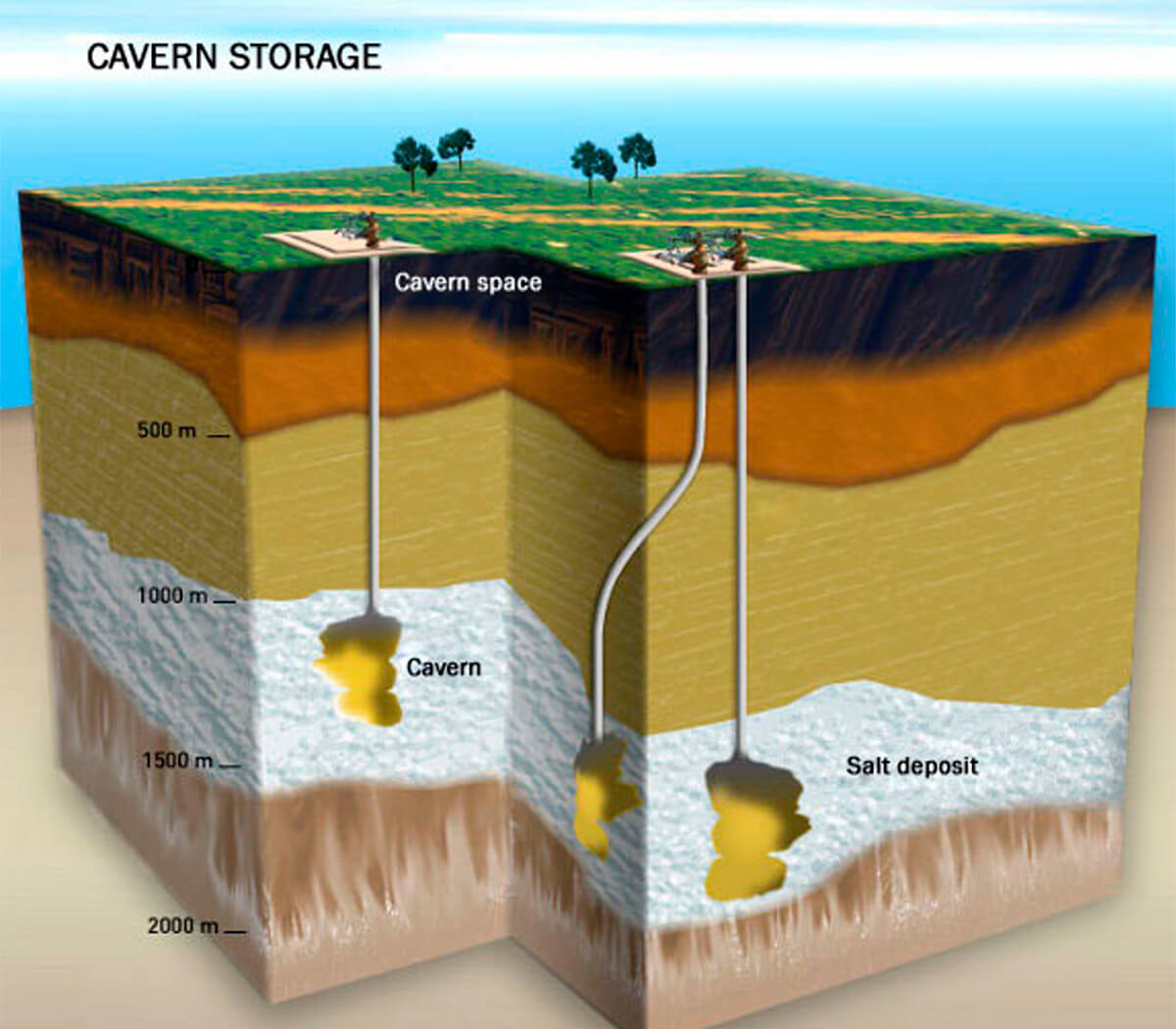

The storage of hydrogen is another key factor that must be addressed. As mentioned in the transportation section above, compression and sending hydrogen via pipeline is one of the most cost-effective methods of transporting hydrogen. However, once you get your hydrogen where you want, you aren’t necessarily going to use it right away, therefore you need to store it. There are many methods, one of which is conversion of hydrogen to more stable and easily transportable forms such as: synthetic methane, synthetic liquid fuels and ammonia (IEA, 2019). These conversion methods are also very useful if you don’t have the hydrogen-friendly infrastructure to ship it but do have the means to convert the hydrogen to something more stable. Unfortunately, a drawback to conversion is the cost, which comes back to the IEA (2019)’s point that although there are factors such as storage and transportation, they will always be trumped by the cost, which again, is one of the reasons that has held back hydrogen technology advancement. Another solution to storage can be found in salt caverns, see Figure 3.

These are large cavities within the subsurface that are ideal for storing gases, a concept which has been proven across the UK, and are currently being presented as a viable option to store hydrogen for extended periods as a backup source of power during times of high demand (Northern Gas Networks, 2016).

Conclusion

To summarize, it might be clear by now that there are many aspects to consider when trying to implement hydrogen as our clean fuel alternative, and currently I believe that cost is the biggest barrier to scaling. Areas where such infrastructure is not available currently, investments (whether they be private or public sector investments) are necessary to transform and build the infrastructure to accommodate more environmentally friendly, blue and green hydrogen production. The reality of our current situation is that grey hydrogen, “is likely to remain the dominant technology for large-scale hydrogen production in the near term because of its favourable economics and the large number of SMR units in operation today” (IEA, 2019). That being said, it doesn’t mean that blue and green hydrogen are distant dreams. In fact, a blue and green hydrogen future of Canada is very much possible by 2050; following the logic of Layzell et al. (2020), “Meeting this domestic demand for hydrogen is probably best done through a combination of ‘blue’ and ‘green’ hydrogen where the relative importance of each would vary with different regions and sectors across the country.” Furthermore, they add that to be able to completely phase out grey hydrogen, this will require enough demand to make the production of the cleaner alternatives to be economically feasible; this combined with Canada’s abundant resources to aid in blue and green production of hydrogen, can lead to clean hydrogen that is able to compete with the low cost of grey hydrogen. 2050 may seem like it is a long way away, but the hydrogen transition is already happening.

Disclaimer

I am by no means an expert on hydrogen, and I gladly welcome any critiques, comments, and questions as I am always ready to learn something new. My opinions are my own, and in no way do they represent the beliefs or opinions of my employers and affiliates. My article was not written with any intention or expectation of personal financial gain.

Acknowledgements

I would like to take a brief moment to thank and give a shout out to Brian Schulte for giving me the opportunity to write this article. From start to finish I have learned an immense amount about hydrogen (with more still out there to learn) and I have Brian to thank for the initial push and guidance throughout.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article