In September of 2018 the upcoming winter season quickly went from decent to dreadful. With the widening of the Oil Differentials, potential projects were cancelled and the outlook for 2019 began to look like the bottom experienced back in 2016.

The CAGC commissioned the following op-ed in order to look back at the history of the industry, where it is today, and what the future potentially looks like. It is intended to be a white paper on seismic.

All industries face cost pressures and regulatory challenges. Briefly mentioned later on in the document that follows these are intended only to be noted in passing as issues the CAGC continues to work towards resolution in terms of operational effectiveness and efficiency.

The case for new uses for seismic is the good news on the horizon. The challenge will be getting the Oil and Gas Industry to arrive at similar conclusions.

The fact an oil service trade association is working harder to support its members and their employees as the issues and challenges mount is a positive sign in this market.

Executive Summary – Why New Seismic Technologies are Struggling to Overcome Old Perceptions

“We shall not cease from exploration. And the end of all our exploring will be to arrive where we started and know the place for the first time.”

T.S. ELLIOT

Canada’s upstream oil and gas industry has changed more in the past ten years than in the previous 60 years following the Leduc discovery of 1947. Leduc marked the beginning of the growth of the Western Canadian Sedimentary Basin (WCSB) from a localized industry to the 5th largest hydrocarbon producing jurisdiction in the world.

Today, production growth is coming almost exclusively from oil sands – mined and in-situ – not conventional reservoirs. It is a resource that has been known about for over 300 years. The combination of engineering, technology and experience has made the exploitation of the world’s 3rd largest oil reserves economic, particularly in this century.

Natural gas production – which grew in volume, price and total value for decades – has seen output plateau and even decline combined with commodity prices that are at a small fraction of historic levels. This has been driven by exploitation of shale oil and gas produced from source rock using horizontal drilling, multi-stage fracturing and other completion and production technologies across North America. Core markets for shale oil and gas, like central Canada, have been lost by western Canadian producers to closer US sources. North America has become an LNG (liquefied natural gas) exporter and the US has risen to become the top producer of oil, exporting at record levels and shifting global markets.

Exploration for new sources of oil, natural gas liquids and natural gas has increasingly been replaced by the exploitation of known reservoirs, long identified and even delineated during past exploration and drilling operations but not economic to develop until recently with the development of new horizontal drilling and completion technology. Resource plays like the Montney, Duvernay, Cardium, Viking and Bakken – reservoirs identified in the past 70 years – now dominate non-oil sands production development spending.

The dramatic changes in production output and method from the WCSB have also changed the structure and activities of both exploration and production (E&P) and oilfield service and supply (OFS) companies.

While all sectors have been affected, no industry has seen more negative impacts from these dramatic changes than that of the business of seismic data acquisition and processing, the primary method used for identifying the location and characteristics of subsurface hydrocarbon bearing reservoirs from surface.

Seismic has long been considered an exploration tool, but as the industry has moved from exploration to exploitation and production, seismic technology has evolved. Advances in recording and processing technologies could allow seismic to become increasingly valuable for exploitation and production operations. Lower commodity prices have led to lower returns on invested capital and the E&P sector has occasionally become cost-conscious to a fault. For example, while new seismic technologies have vastly outplaced the old perceptions of what seismic is, and where it can contribute to enhancing E&P company return on invested capital, cost control measures have prevented E&P companies from realizing those technology-based gains.

While the role of seismic has changed, its existence as a key and fundamental component of the upstream oil and gas industry has not. The rest of the document will refer to the history of seismic and explain why it remains critical to the future of the upstream oil and gas industry.

What Is Seismic?

Website dictionary.com defines seismic as, “pertaining to, of the nature of, or caused by an earthquake or vibration of the earth, whether due to natural or artificial causes”. It was originally the detection then measurement of vibrations of the earth following an earthquake, or a seismic event. In the late 1800s inventors determined artificially created sound waves from surface might help identify the shape of subsurface geological structures when the returning signals were recorded and analyzed.

Subsurface accumulations of oil and gas were originally identified by seepages to surface, but obviously this was only a tiny fraction of what might exist below. Early in the 1900s seismic was being used to identify subsurface structures that were easy to spot, such as large salt domes. In the first half of the 20th century seismic was refined to become a key element of the oil and gas exploration processes. Seismic allowed large areas to be cost effectively examined for hydrocarbon bearing potential, compared to the more expensive and less reliable process of exploratory wildcat drilling.

Seismic data acquisition and processing was refined in every way with the evolution of technologies – seismic sources, surface recorders, improved sampling rates, digital telemetry, 3D seismic acquisition, stacking, migration, inversion and the list goes on.

In the WCSB, by the late 1940s seismic was the “go to” tool in exploring for promising subsurface structures that might contain oil or natural gas. Seismic companies, crews, cutlines, jobs, and a vast and deep seismic support infrastructure became a key element of the WCSB’s upstream oil and gas industry. Seismic was, and remains, as essential to oil and gas exploration and development as better-known equipment and services such as drilling rigs, pumpjacks, trucking, construction, pipeline, gas plants and oil refineries.

Globally, seismic continues to be a key exploration tool in many hydrocarbon bearing basins. The province of Newfoundland and Labrador (NL) recently conducted a major seismic exploration program of its own continental shelf to attract new exploration and production activity to its jurisdiction.

Seismic Shifts in the Seismic Business

The demand for seismic services in the WCSB has declined precipitously in the past decade to the point of the near-collapse of its historic business model. These factors include:

- The collapse of natural gas prices and natural gas exploration

- The move to “resource plays”, which exploit the laterally extensive source rock directly, making the identification of local conventional targets essentially obsolete

- The availability of public well data from the many thousands of wells to identify laterally extensive source rock characteristics from existing drill logs to inform resource plays.

- The availability of large non-exclusive 3D surveys that were sparsely acquired and under sampled (today these are of little use to identify rock properties essential for resource plays)

- The 2014 oil price collapse which has caused E&P companies to review all expenditures for cost, efficiency and necessity

- The significant reduction of the economic viability of all oil and gas operations in the WCSB due to commodity prices, market access issues, “made in Canada” prices (the lowest market-set oil and gas prices in the world), increased taxes, increased regulations, and growing public opposition to the existence of this industry

- The lack of Industry understanding and appreciation of seismic technological advancements, resulting in a lingering false perception that seismic is purely an exploration tool with limited value in exploitation and production operations

- Supply Chain Management processes that prevent open project discussions with clients and contractors

- Contractor investments in technology have increased recording productivity to the point where crews shoot low quality projects faster (reduced costs) while unable to leverage the technology to improve subsurface imaging through higher density projects.

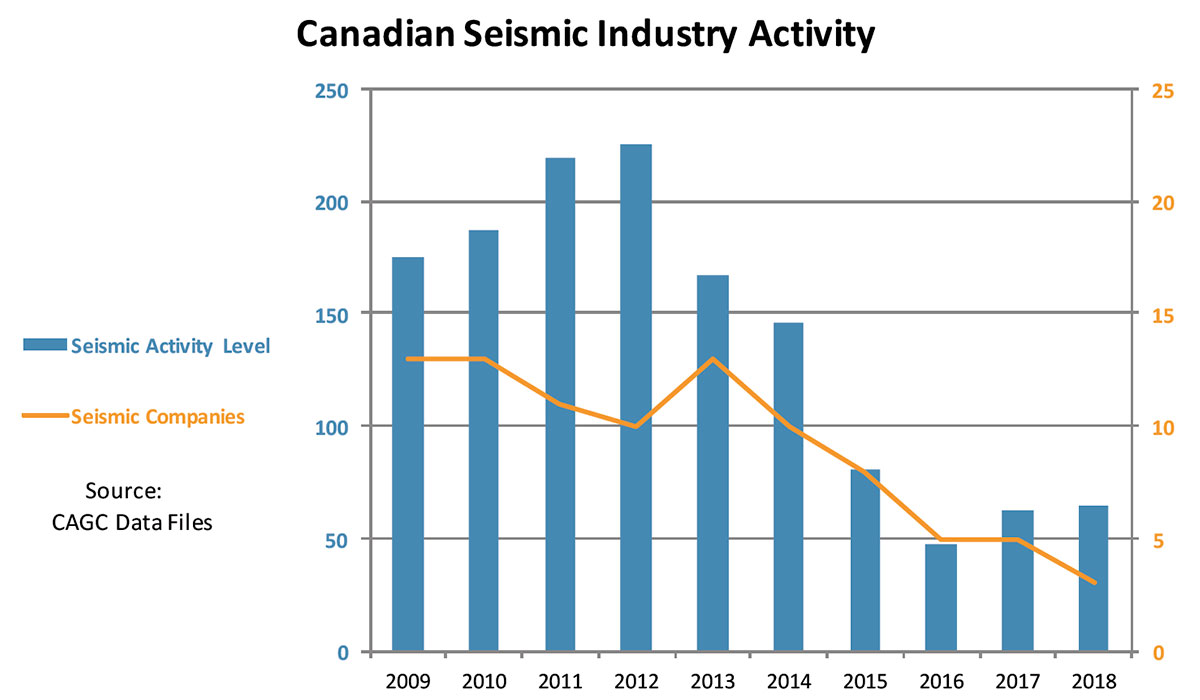

The impact on the seismic sector is particularly acute. The most common measurement of seismic spending and activity is the “active crew count”, the number of seismic survey and data collection crews in the field on a given day.

The decline from 2008 to 2009 was caused by the world financial crisis and the resultant impact on commodity prices. A recovery began in 2010. The growth of the “light tight oil” (LTO) development in 2011 and 2012 caused a surge in activity as E&P companies delineated new areas of interest in Alberta and Saskatchewan. Following the oil price collapse of 2014, the general downward trend has become more pronounced.

The contraction of the industry has been significant. In 2002 there were 20 data recording companies in the field. There are two characteristics of the activity downturn that have been particularly damaging to the seismic industry.

Focus on Price

Client focus seems to be strictly on price resulting in sparsely acquired, under-sampled data. While Canada has long been recognized as leaders in the geophysical acquisition industry, there are many that would suggest Canada is lagging when it comes to sampling data effectively. The focus on cost per square km and the “it worked before” attitude has likely limited exploration and development applications of seismic data. The contraction in the number of seismic company participants in this sector has been particularly acute. This is particularly challenging for the seismic sector where over 50% of the work is done in a 2-month period starting in mid-January and ending in mid-March. Providing clients with trained and qualified personnel to work for only 8 of the 52 weeks in the year is particularly difficult.

Supply Chain Management processes have reduced or eliminated contractor / client pre-project discussions that reduces equipment utilization and or other potential opportunities. In many cases, clients no longer have the in-house operations expertise required to achieve optimum operational efficiency and contractors cannot communicate these opportunities with Supply Chain individuals whose focus is solely on price when selecting contractor services.

Perception of Seismic Utility

The second is a perception that seismic is primarily an exploration tool that has limited utility in shale plays. A change is required that focusses on the viability and necessity to conduct seismic sensing, evaluation and monitoring for resource plays and in the cost-effective exploitation of known reservoirs.

To the end of 2017 there had been over 530,000 wells drilled in the WCSB. Because of government requirements, most of these wells have been open hole logged (electronic devices have determined and recorded geological properties and depth). Many have been cored (actual reservoir samples of natural rock cut, recovered and logged), and rock cuttings (rock samples created by the drilling rig bit), captured at surface, recovered and catalogued.

Virtually all this well data is on the public record and available to E&P companies and this has given modern oil and gas developers “well control” (an understanding of the properties of a reservoir not-yet-drilled). This information did not exist in the earlier phases of development of the WCSB.

Further, all seismic data ever collected is stored and much of it is available from private companies for resale and/or reprocessing. If seismic is required, many E&P companies have concluded that they can purchase, and review sparsely acquired existing data as a lower cost alternative to acquiring new data.

Therefore, a growing number of E&P companies, particularly those focused more on cost than reservoir characteristics, no longer regard new seismic as a key component of the exploitation and production process even though newly acquired seismic data is vastly superior in quality, resolution and definition.

The result of the foregoing has been devastating on the seismic industry. As recently as 2008 there were 10 companies left in the seismic data recording sector in Canada, of which only 3 remain today. Whether or not all three will still be active in Canada a year from now is unknown. 2 will evaluate the future of their Canadian operations based on competing opportunities in international markets. The 3rd will only remain in business if the current owners have the financial capacity and commitment to stay operating until a recovery takes place, the timing of which is unknown at the present time.

How Seismic Has Changed

There are several factors that make the seismic industry as relevant today as it has always been. They are not universally understood or appreciated by clients or regulators.

Today’s Oil and Gas Recovery (introducing and relieving reservoir pressures)

Historically, oil and gas producing reservoirs were naturally highly pressured. In the era before secondary recovery techniques – SAGD (steam assisted gravity drainage), steam injection and horizontal drilling and multi-stage fracturing – the exploited reservoir was over-pressured, and production achieved by draining it and exploiting this pressure. Recovery from today’s low or zero pressure reservoirs- is achieved using artificial pressure injection from steam or by opening pathways for hydrocarbons to flow up the well bore using hydraulic fracturing. These operations can be enhanced using seismic sensing and monitoring. Early examples of steam injection breakthroughs to surface have caused caprock integrity to emerge as an issue of concern and the importance of seismic analysis. Increasingly larger and higher-pressured fracking into non-contiguous reservoirs or those with faults that allow the “frack” to escape along the fault fail to contain the frack in the target reservoir and can induce undesired seismic events including small earthquakes.

Advancements in Seismic Technologies for Data Collection and Analysis

Early seismic testing was only able to detect the most obvious subsurface structures, such as large dome-shaped traps. Advancements in data collection, particularly in wireless recorders and recording instruments to collect data from more sensors, have dramatically increased the granularity and accuracy of the subsurface analysis and identification process while at the same time it has reduced the cost of the data acquisition and recording process. These new methods have allowed geophysicists to examine subsurface structures with a degree of detail that did not exist previously. While the volumes of existing, sparsely acquired data are significant, their usefulness for today’s exploitation and production operators who look at the reservoir caprock or detailed rock properties within the reservoir is limited. Further, for reservoir delineation prior to in-situ or bitumen mining operations, seismic is a useful, cost-effective and environmentally benign method of delineating reservoir depth and caprock integrity and compliments conventional coring.

Seismic Not Just an Exploration Tool

Seismic is the best/only tool available to analyse and understand how a reservoir and the formations above, below and nearby it will react to high pressure during exploration and production. Seismic is already required to ensure caprock integrity for thermal bitumen recovery operations at shallow depths. Seismic can also be used for improved recovery in SAGD operations, improved horizontal wellbore placement and completion, understanding secondary production, and identification of the risk of induced seismicity from hydraulic fracturing.

Thermal Recovery: Operators of existing SAGD and thermal bitumen recovery projects are increasingly using seismic to analyse how producing reservoirs are responding to ongoing thermal operations. As one seismic industry veteran commented, “No one would do anything in the steam world without seismic.” This can include the identification of “steam chambers”, steam breakthrough and other phenomena in the reservoir which can radically increase costs and reduce recovery.

Horizontal Drilling and Multi-Stage Hydraulic Fracturing: Customers have begun to use seismic recorders to monitor and analyse hydraulic fracturing operations as they take place during horizontal drilling, fracturing and well completions (microseismic).

Other operators now understand the value of using seismic to analyse the characteristics within a known reservoir before high pressure, high volume fracturing, rather than just using existing information to delineate the location, top and bottom of the reservoir itself.

One operator used modern seismic to analyse a reservoir before drilling. When natural faults were discovered, the client realized a high pressure; high volume fracturing treatment in that section of the reservoir would be a commercial failure before the well was drilled as the frack would not be contained in the target location. In this respect, even though this was not an exploration investment in the classic sense, it was the application that put seismic on the map in the first place: invest a smaller amount of capital up front before drilling to minimize the risk of failure and maximize the return on investment.

Advancements in seismic technology have given clients a better understanding of the properties of the reservoir through which 1 or more horizontally drilled and multi-staged fractured wells are planned. Understanding the properties of the specific reservoir permit advanced “geosteering”, the process by which a directional drilling assembly is guided through the reservoir. Using the analogy of surgery for a medical intervention, a seismic veteran commented, “Who would do a complex medical procedure without an image?” In an interview in the October 1, 2018 edition of E&P Magazine, Mike Bahorich, former Chief Technology Officer for Apache Corp., stated, “Among the largest super-independents, there are some that have had tremendous success using seismic to maximize the value of their shale assets. Almost all the shale players use seismic for geosteering, and I cannot imagine geosteering without it.”

In the same article, Dave Monk, director of global geophysics for Apache Corp, talked about understanding the reservoir to ensure proper spacing of wells to ensure maximum hydrocarbon recovery without having multiple reservoirs in the same reservoir communicate with each other during and after hydraulic fracturing. Monk said, “The biggest issues that people have with the completions are trying to determine how far apart the wells should be, how many fracks they should do, and how many stages should be in a lateral, and those completions engineers have not determined that yet. They don’t think they can get their information from the seismic. They understand where they’re going to geodrill…(but) the problem that they all want to solve today is how far apart to put the laterals and how many stages they should drill. Geophysics might be able to help them”.

Allen Gilmour, co-founder of Drilling info commented on how many E&P companies use seismic on a regional basis, but not on a well or project-specific basis. Gilmour added, “…where I think seismic would really shine, is what I call location-specific optimization, which means how they complete a particular location because the rocks look alike (similar and/or homogeneous on existing seismic) or because of their proximity to faults… seismic is critical for that. And the amount of hydrocarbon to be had from going from regional to specific is probably 20% or more.”

Evaluating Secondary Recovery Operations: Modern seismic can detect activity within a reservoir not previously available. Alberta’s Pembina Cardium formation has been producing oil since the 1950s and continues to do so today. One operator was not getting the desired results from a waterflood for pressure enhancement and increased oil recovery, so a modern seismic survey was conducted completely on a township. It was then compared to a similar seismic program conducted on a township nearby not subjected to waterflooding. The operations manager and geophysicist involved in the project said, “We could actually see the impact of the waterflood. We mapped out on seismic the pressure response of the waterflood and confirmed the physical properties of the waterflood. While the water injection was opening some reservoir channels it was closing others.” The result was adjustments in the water injection process which increased recovery and reduced costs.

Seismic for Prevention of Induced Seismicity from Fracking: It has been noted in several areas across North America that in certain areas of active natural geological activity hydraulic fracturing can induce greater earthquake activity. Earthquakes, a natural seismic phenomenon, occur in places where natural fractures allow sections of the earth to slip or slide thus causing ground disturbance of varying degrees. The well-known San Andreas fault on the western edge of North America is a known and large natural fault. High pressure from oil and gas operations does not create the type of fault or fracture that causes tremors or earthquakes, but the introduction of lubricity agents like frack fluids or nearby seismic activity can accelerate natural geological movements. Seismic can help operators identify regional subsurface structures that could be affected by oil and gas activity.

Seismic Cost-Effective on a Per-Acre Basis

In the same article in E&P Magazine, Richard Degner, president and CEO of Geophysical Technology Inc., explained the cost of seismic in the same economic terminology that investors and oil analysts evaluate oil and gas company spending. “…I don’t understand E&P execution the way that these guys do (Apache Corp.), but I do see how for $50 to $100 an acre we can record a seismic survey that has a sampling of 4 million or 5 million traces per square mile. Twenty years ago, we were recording 20,000 or 30,000 traces per square mile. These operators are leasing land for $30,000 or $40,000 per acre, and they are drilling and completing it for another $20,000 or $30,000 per acre. If you spent 10 times that much more and had 5% better execution, or even 1% better execution, isn’t that an amazing payback? The industry recorded surveys 25 years ago at 20,000 traces per square mile for around $100 per acre and is now using high technology and exceptional logistic execution to record surveys with many millions of traces per square mile for $100 per acre. At that price we’re talking about, when you’re paying $50 to $100 per acre while spending $60,000 to $80,000 per acre to lease and develop it, it always matters.”

The WCSB Deserves Another Look

Based on the foregoing, there is a strong case to review most of the major areas of interest in the WCSB. Much of the existing seismic data, which clients are hoping to use as a low-cost alternative to new data, is of little value. As importantly, the cost of acquiring new, high-tech seismic information remains as it has always been; a fraction of the cost of drilling and completion and an even smaller fraction of an exploitation or production investment in a reservoir that could become a huge economic or environmental failure due to caprock or natural reservoir faulting and structural challenges, discovered after abnormal pressure from surface has been applied to a reservoir that had little or no natural pressure. The cost to acquire a modern 3D seismic survey on a potential per drill location basis is background noise in comparison to the drilling budget. The costs of drilling and completions per well are significant, and while the seismic is often considered an up-front expense, if factored into the overall cost of development it is a minimal expense, compared to the insurance it provides.

Regulatory Complexity

Like every other aspect of Canada’s upstream oil and gas industry, seismic has been subjected to a myriad of new legislation and regulations designed to ensure enhanced stakeholder engagements and more environmentally benign operations. The CAGC continues to work with the Regulators and Politicians to educate and minimize impact to our operations.

Seismic on Lakes – In 2007 the then Alberta Premier, Ed Stelmach declared that no seismic activity would be permitted on Marie Lake, a recreational body of water in northeast Alberta north of Cold Lake in an area well known for extensive oil development. A CBC article dated September 4th, 2007 read, “Premier Ed Stelmach has halted a plan to conduct seismic testing under a pristine lake in northeastern Alberta, reversing a cabinet minister’s earlier decision. ‘I have decided that seismic testing on Marie Lake will not proceed’…Cabin owners in the area, who had protested the testing, were overjoyed with the Premier’s decision”. While no specific laws or regulations for creating seismic signals within a waterbody have even been drafted in the past 11 years, the former Premier’s pronouncement continues to obstruct industry activity as operators unsuccessfully seek regulatory approval. Meanwhile, environmentally responsible seismic acquisition on waterbodies continues apace in other jurisdictions around the globe, and new technologies are being deployed to facilitate this work.

Riparian Areas – Alberta Exploration Regulation 2006 – 16 sets the regulations for what is called “Riparian Setback”, the minimum distance from a body of water at which seismic operations can be conducted. It is defined as, “Riparian zones are buffers to ensure minimal disturbance to vegetation and minimize the potential of flowing shot holes on public land. An aquatic buffer is an area extending a minimum of 10 metres into, or through the riparian area beginning at the water’s edge of a water body or watercourse or the bank immediately next to the water channel.” This impairs the ability of the seismic industry to obtain consistent data and can discourage clients from conducting seismic surveys in water-prone areas because of poor data coverage and higher costs. Further, the definitions are not concise. For example, “A riparian area is a variable width zone on either side of a water body or watercourse where the majority of the vegetation is aquatic”. Additionally, new technologies are now available to enable environmentally responsible acquisition with near-zero impact in riparian areas.

Caribou/Species at Risk Protection – Industry and provincial regulators continue to have difficulty interpreting the impact of these regulations. However, CAGC members have achieved significant progress in reducing line widths and are working hard to further reduce line widths and environmental impacts with new methods and technologies.

Indigenous Consultation – Consultations with indigenous communities regarding access and use of traditional and treaty lands remains an important and dynamic issue among indigenous people, industry and regulatory stakeholders.

Safety and Training Requirements – CAGC and the seismic sector share the commitment of all stakeholders to create the safest possible work environment. The cost to prepare a new worker for the field runs in excess of $3500. The industry has been working towards standardizing an on-line Common Safety Orientation (CSO) for all new workers to the industry in all sectors. It is hoped all Operators will accept this standard in lieu of company developed equivalents.

Labour Challenges in the Seismic Industry – The reduced activity and compressed seasonality are causing new challenges for the seismic industry. Retaining full time personnel is impossible and qualified seasonal labour is increasingly difficult to source. The continued increases and potential increases in safety training and compliance costs in the face of economic and labour challenges, combined with a reluctance by regulators and clients to acknowledge, let alone rectify the problems, further jeopardizes the financial health of this vital industry sector.

Why the CAGC Matters

The CAGC was founded in 1977 as a voice for the seismic and geophysical contracting industry. In its first 40 years CAGC has established itself as a strong voice for its members, owners and their employees. The mission reads, “The Canadian Association of Geophysical Contractors (CAGC) represents the geophysical industry in Canada and promotes the industry as a world leader in the development and application of advanced geophysical technologies.” Its main areas of focus are government interaction, communication with other industry trade associations in areas of common interest, education and information, media liaison and communications, and safety and training. The only trade association that has existed in its current form longer than the CAGC is the Canadian Association of Oilwell Drilling Contractors.

The CAGC is important for its members and industry because of the unique nature of the seismic business and its operations. Seismic is in fact a “subsurface surveyor” in the sense that its products are information, data and knowledge. In new exploration activities, seismic is ahead of all other industrial activity including roads. It routinely operates in remote areas where there has never been any industrial development. In Canada its operations have historically been seasonal which creates unique challenges for running a business, from finance to human resources.

Because of this, the CAGC works on behalf of its members, owners and employees to address regulatory, administrative and business issues unique to the seismic industry. Past and continued support for the CAGC is evidence that the seismic industry in Canada is in a better place today than it would have been without its existence.

A major change in the relationship between the seismic sector and its clients and government regulators is the increase in complexity and administrative costs of the upstream oil and gas business. The regulatory burden – from within and outside of the industry – has increased dramatically compared to when the CAGC was founded in 1977. The industry is also much larger and diverse than it was forty years ago as measured by the volume of oil and gas produced.

Another major change is that the upstream oil and gas industry has become increasingly politicized. The issues dominating the public agenda are production volumes, pipelines, taxes, royalties and increasingly, the very future of non-renewables and the industry itself.

Therefore, attracting customer and regulatory attention to important issues regarding the current and future affairs of the seismic sector in particular – details like those discussed above – is increasingly challenging. When associations, elected politicians and regulators do have time to deal with the specific issues of the seismic industry, their preference is to talk to the association representing multiple companies and stakeholders, rather than individual owners or officers of the many industry companies.

The changing face of the seismic industry, combined with ongoing economic challenges, has forced existing and potential CAGC members to examine every expense, including the cost of membership. This has resulted in a situation where, at the very time membership in the CAGC is of most importance, retaining and attracting members is the most challenging.

As the seismic industry remains concerned about its future, it should also be concerned about the future of its voice. There is a clear business and economic case that the CAGC should have more members and support in the current business environment, not less. Further, E&P companies should consider supporting CAGC through associate memberships to ensure that when they need essential seismic services, they will still be available from competent, responsible and economically viable service providers.

Conclusions

- Seismic is as relevant as it has ever been, a key component of cost-effective oil and gas recovery.

- Because of advancements in technology, seismic has moved beyond exploration into exploitation, production, recovery and the mitigation of unintended consequences with caprock or adjacent formations

- New technology has rendered old 2D and 3D seismic all but obsolete. In the era of 4K HD television, old seismic is the equivalent of a black-and-white cathode ray tube television

- Relative to cost of major exploitation projects, such as a horizontal well pad, the cost of seismic is minor for the ability to achieve a higher return on investment and higher production and recovery levels, by using high density seismic to deliver incredible value

- Modern seismic techniques and technology can now deliver far superior information with a much lower environmental footprint

- Because of the up-front role seismic plays in the exploitation process, impediments to cost-effective seismic are obstacles to major investments, job creation, taxes and royalty income

- At the present time the Alberta government is increasingly concerned about the health and future of the upstream oil and gas industry. The door is open, more than it has been in years, for industry to advance suggestions on how the province can assist through this difficult period.

- Industry trade associations are increasingly relevant to represent the interests of members and the oil and gas industry with regulators, politicians, other trade associations, and clients. CAGC has been effectively fulfilling this important role since 1977 and now, more than ever, deserves continued support by all stakeholders including customers.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article