It’s 1965, and a new standard is being rolled out in the Canadian petroleum industry. Designed by industry, for industry and adopted as a standard by the Canadian Petroleum Association (CPA), it became known as the CPA UWI (unique well identifier). In 1965, Lester B. Pearson is the Prime Minister of Canada and the most popular vehicle is the Ford Mustang GT 350, which could be purchased for around $2500.00 and power steering was becoming a standard on all vehicles. The big names in the energy sector are Amoco, Conoco, HBOG, Gulf Canada, Canadian Pacific Oil & Gas, Dome Petroleum. Today artifacts of these companies exist in our vast data stores. Look how far the industry and technology has come, hand in hand together. In 1965 we worked primarily on paper, with well files and paper maps. About this time, we are testing cyclic steam in the “Tar” sands. The predominate well profile was a single vertical borehole, and the CPA UWI was the standard identifier, used by all disciplines, across the well’s life, from licensing to the end of life. The CPA UWI is a descriptor by nature tied to the bottom hole of the borehole and because of its descriptive nature gives us immediate valuable information. This won’t change.

But let’s have the conversation about change: how many of us are still driving that Ford GT 350, using the same fridge from 1965, sporting the same haircut?

Wells are critical assets for energy companies, and well data represents our understanding of the subsurface, the rocks, the steel and equipment buried deep underground. Since 1965, our technology has changed, how we drill wells has changed and yet the unique well identifier (UWI), designed and implemented 54 years ago, has not changed. In 2019, the industry requires an identifier that will address the way we do business today, the way we drill wells today. Let’s explore those business requirements driving the necessity of this change in this article, focussing on answering why we might want to add a new well identifier to our tool belt.

The CPA UWI, designed to be an intelligent identifier, indicates the bottom hole location of your wellbore and positions your well to a map location easily recognised by most Albertans. In theory, the CPA UWI also carries the sequence of drills on the legal subdivision and the operational activity of the well. The single boreholes we drilled in 1965, vertical wells where changes to the UWI were rare, are no longer the predominate drilling configuration. In response to technology advances and environmental responsibility, single vertical wells have been replaced by wells with many boreholes drilled from a single surface hole or pad configuration. As the well is licensed, drilled and matures through its lifecycle, managing well data with a standard built in 1965 that doesn’t match how we do business in 2019 has become a data management challenge, costing oil companies millions of dollars. As the pressures for social responsibility and the technology advances to achieve more economical drills, wells will become even more complex, with smaller surface footprints and so we must adjust the processes we use to manage the data. The identifier we use to track and manage wells needs to address today’s wells; with many boreholes, many completions and long drill lengths that make relating the full well family together extremely challenging. Enter the Canadian Well Identifier System (CWIS – sea-wiss), a permanent well identifier, with minimal information stored within the identifier, none of which will change over time. The CWIS was developed by industry experts, from varied functional areas, who live the challenge of well management across our industry every day. The CWIS is good for our industry and will co-exist with the CPA UWI. The UWI will remain as a descriptor, but the CWIS will be the key identifier linking well data across public and proprietary systems. Let’s follow a well from concept to reclamation and see how the CWIS helps.

A well begins its life as a concept from the creative minds of geoscientists, within the walls of an energy company. Within those walls, the well can be called (identified) by any name or label, as the science is shared among those working on that well, all sharing that common vision. As this prospect well matures within the organization, passing through stage gates or funding points and different teams / functions of an organization, the identifier may become more formal as required. The work that takes the well from creative concept to prospect, and on to funded prospect and then to licensing is most often done in project based applications.

Today we use the CPA UWI as the unique identifier in applications. Each borehole from a well (family) is managed separately, with only the knowledge and expertise of the asset team being able to relate them together. This practice means we cannot easily relate multiple bottom hole locations and / or event sequences together to understand the drilling configuration of the well (family). Lots of valuable data is being generated as an asset team works up potential reserves, economics and regulatory requirements. Different roles across organizations each think of a well differently, and in the concept phase of the life cycle, a well may have many identifiers, for each proposed borehole or completion. Using the CPA UWI, to manage these complicated relationships could mean well data is associated to the wrong well bore. Not okay by anyone’s standards.

Imagine your own family, with aunts, grandparents, children, possibly from different countries who likely do not know each other. The descriptors are the last names of the individuals, but the identifier that links these individuals as a family is the DNA.

The current process is, once an organization approves the well for expenditure and a license is applied for, the Alberta Energy Regulator (AER) assigns the CPA UWI, for the first borehole of that well (one license= 1 bottom hole CPA UWI). A surface location for that license is also known and identified geographically within the license. This process will not change fundamentally, with both a surface and a borehole CWIS assigned by the AER at licensing. This behavior follows the standards for naming and managing well components, developed by the Professional Petroleum Data Management (PPDM) Association and can be referenced in their published “What is a well” documentation. The CWIS assigned to surface location forms the trunk of the well family identifier. Once the operator submits to the AER the Drilling and Completions summary and directional surveys, each unique component (borehole, reporting stream (i.e., completion)), will be assigned a CWIS. The CWIS will build out with identifiers being assigned to each component that is defined within the “What is a well” from PPDM. Knowing that the CWIS provides identifiers and the framework to manage each of the well components is critical to understanding what the CWIS can do for your organization. The CWIS will not change over the lifetime of a well, from concept to reclamation.

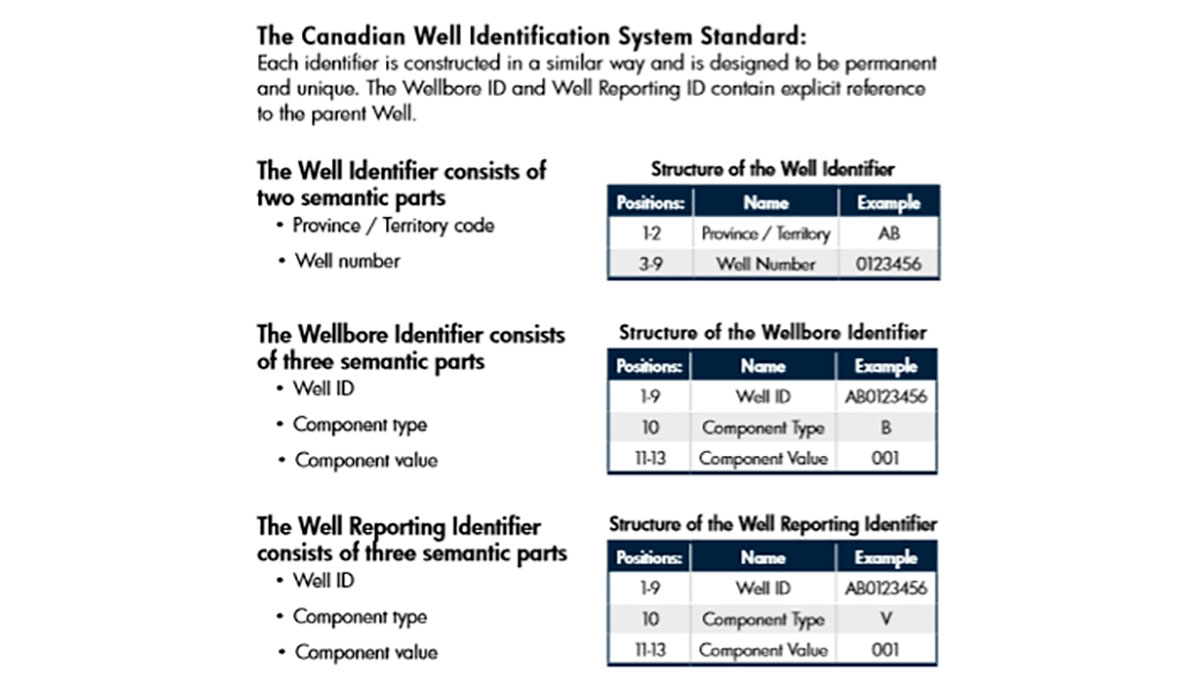

Let’s begin by breaking down the parts of the CWIS.

The CWIS gives the industry a permanent identifier, allowing for changes (amendments) that occur with the CPA UWI, to be handled the same way as any other descriptor. The CWIS also is not limited to 9 event sequences, breaking a historical barrier which has been extremely challenging for operators, regulators and data vendors in managing the information around wellbores/completions. The CWIS will not change over time. The only information within the CWIS is the province and the component type and therefore will remain permanently assigned to that well component. Each well component in a drilling configuration of a well family will share the 1-9 position, the 10th indicates the component type (borehole or reporting) and the 11-13 position is the permanent identifier value. For those who work in the beginnings of a well lifecycle, you may be questioning the need for the CWIS, and that is understandable as those functions are only involved for a short time and then move on to other wells. For those in well data management or those who rely on the historical data, the CWIS gives the industry the opportunity to vastly improve processes and management, and by doing that provide the framework for lookbacks, and other analytics which will add great value to the industry.

To commit to implement this change, organizations need to understand there is a strong business value statement. Without that business value statement, management will not attach resources, do the planning and change management to make the implementation of the CWIS successful. Certainly, the CWIS addresses the challenge of the ever changing UWI, and the more than 9 event issues, and it is a driven regulatory change, but that’s likely not enough business value to drive this change forward. What else does this new identifier bring that strengthens the ROI for the change?

The CWIS has the potential within organizations to address well data management challenges and the opportunity to make the data work for them, reducing risk, cutting cost and building a better well economically. Additionally, C-level management must further the vision of that value statement at an even higher level, recognizing the CWIS as part of the organization’s digital transformation. Simply put, CWIS enables the tracking of assets by well component, and thereby facilitates analytics on each well “family” to a level that has never been possible before. If we recognize, as an industry, that we are aligned with manufacturing industry models, by using the CWIS to track and identify every major aspect of our well family asset, we can fully understand the downhole configuration and this opens the possibility of predicting the success of each model number (well family). Imagine a world where you can analyze every well in your area, both historical and currently drilled, and use those models to build a better well. Organizations who adopt and use the CWIS as the key, will provide the means for their people to easily know the number of boreholes, calculate any number of parameters like length of reservoir contact, or production by meter of borehole. By stabilizing and maintaining the complex relationships between all the components of a well “family” together, additionally knowing the component types, the well asset becomes clearer and easier to analyze. Today to accomplish this, the industry relies on the data from many disparate systems, much human intervention, to review and manipulate the data and relies on the “asset team memory” (ie., the people). A CWIS in the public data will enhance an organizations ability to evaluate performance against their peers, think of how this might change the A&D world. The CWIS has the power to potentially impact many processes positively. Implementing the CWIS correctly moves the oil industry forward towards digital transformation.

The CWIS will co-exist with the CPA UWI, but recognizing the strengths and value of each identifier will be the strongest solution for companies to adopt. The CWIS is built for today’s well configurations and today’s analytics tools.

The industry has a fierce loyalty to the UWI, which has worked brilliantly for decades, but those organizations that can see forward to marry the CPA UWI with the value of the CWIS, will be the leaders in the analytics revolution. Let’s use an analogy of a 1965 muscle car to a modern vehicle, we have a fierce love of that muscle car, but the new one has driver alerts, automatic parallel parking, hatch foot activation. We are still driving a car, but likely very few of us would choose to give those new features up, once we are comfortable with them. This period of adjustment has a payoff, with these new vehicles, our streets are safer, our families are safer and our lives are enhanced. We need the CWIS to create the new car, the one where analytics, and automation in managing wells is technically plausible. Adopters in the industry can leverage and capitalize on these inherent benefits. The CWIS has the potential to do a quiet, critical digital disruption in well data management. So, with some mindful planning, management vision and thoughtful implementation, as we move into this brave new paradigm, remember – we’ve got this.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article