Cableless, wireless or cable-free (we will use the term cableless in this discussion) seismic recording systems do not transfer data back to a central recording system and they do not transfer power to multiple stations through cables. The majority of them are autonomous with the data being recorded on flash memory at the station with a battery and sensor (geophone or accelerometer). Even though they are called “cableless” they still use cables to connect the geophones and external batteries. They range from completely autonomous to being able to transfer data via some form of wireless transmission (WiFi, BlueTooth, multithreaded (or mesh) RF, etc.). In this paper we will discuss the various advantages and disadvantages of cableless seismic acquisition systems and compare the overall functionality of cableless systems to cabled systems. We will also briefly review the various cableless systems and their similarities and differences.

Centralized Radio Systems vs. Radioless

For 20-30 years radio units have been used for communication by VHF (100-300 MHz). These units have a range of tens of kilometres and were favoured to preserve the near real time data collection and transmission. They allowed for breaks in receiver lines due to major roadways, large rivers, large ravines, etc.

The major breakthrough in cableless recording came with the development and availability of low cost, low power miniaturized GPS chips. The GPS chips are not only used for positioning, they are also used as a synchronization clock to time stamp seismic samples. This accurate timing (30 ns) has been the key to eliminating centralized radio systems and allowing for truly autonomous recording. Continuous improvements in battery life, low power consumption and high capacity flash recording have also contributed to the growth of cableless seismic recording.

Perceived Advantages of Cableless Acquisition

Cableless recording systems (Figure 1) are becoming more common for seismic acquisition. The advantages of a cable-free system are numerous.

- Flexibility to deploy across roads, rivers, no permit zones, congested areas, environmentally sensitive areas and other demanding terrain

- Higher productivity with no downtime for cable repairs (animals and equipment)

- Reduced crew and transportation costs

- Reduced maintenance

- No predefined cable or receiver intervals

- Improved safety and reduced risk of injury

- Highly scalable

- Small and lightweight

- Potential to record multiple spreads

- Potential to record far offset data (refraction) simultaneously

- Continuous recording for microseismic applications and passive monitoring

- Eliminates serial reliability issues

These numerous advantages really boil down to three major categories – higher productivity, reduced costs and improvements in HSE.

Perceived Advantages of Cabled Acquisition

While the appeal of cableless systems is growing there are still applications for cabled systems (Figure 2) and the new cable systems have become lighter, smaller and require less power. By far the most appealing aspect of cabled systems over cableless is that you do not have to shoot “blind”. Some clients are not comfortable with the idea of blind shooting for reasons such as wind noise. For very tight receiver intervals it could also be advantageous to use a cable system since the weight requirements are constant for a cableless (about 4-5 Kg/station) system yet scale down with a cabled system as the receiver interval decreases. Cableless systems also present a data security issue in that if one of the boxes is stolen or lost then the data is lost for good. Finally the data harvesting is faster and requires less equipment for a cable system. While a cableless system will have less equipment in the field than a cabled system it will have more equipment back in staging in the form of data collection and battery charging stations. The data harvesting itself can add numerous days to the overall field time.

A Brief Discussion on the Development of Cableless Seismic Systems

It is broadly accepted that the first known seismometer (it also happened to be cableless) was the Seismoscope developed in 132 AD by Zhang Heng and interestingly enough patented in 1571. The Seismoscope (Figure 3) was comprised of dragons, drop balls and frogs. The dragons held the drop balls in their mouths until experiencing ground motion from a particular azimuth. The azimuth of the incoming event correlated with the position of the frog into which the ball fell.

Remote seismometers have been used for earthquake detection for decades. Early models would have had various recording media including pen on paper drum recorders, tapes (including Sony Walkmans) and now flash memory and real-time data streaming. The remaining elements of the system are basically unchanged from the first systems and share the basic setup of todays most advanced cableless systems.

The system requires power that is typically provided by solar panels and batteries, a sensor that is typically a 3-component broadband seismometer and a recording unit with GPS and a modem.

Cableless Seismic Acquisition Systems

Most of the major seismic acquisition system manufacturers offer a wireless option with some of the companies in the market only providing wireless solutions. All systems share the fundamental architecture that is described above for remote earthquake seismology recording. That is a sensor (1-C or 3-C geophone of accelerometer), GPS, battery, flash memory and in some cases an antenna. The big difference is the volume of data. Active 3D surface seismic systems will record in excess of 10-20,000 channels and transmitting these volumes of data is challenging. Hence the majority of cableless systems are autonomous with data retrieval or harvesting occurring many days after the shot was taken.

We will show each system and provide a brief manufacturer’s quote. Listed, in no particular order, are the cableless systems that the author was aware of as of October 31, 2015.

| IMAGE | SYSTEM |

|---|---|

| 1 | Inova – HAWK |

| 2 | Sercel – Unite |

| 3 | FairfieldNodal – Zland |

| 4 | Geospace Technologies – GSX |

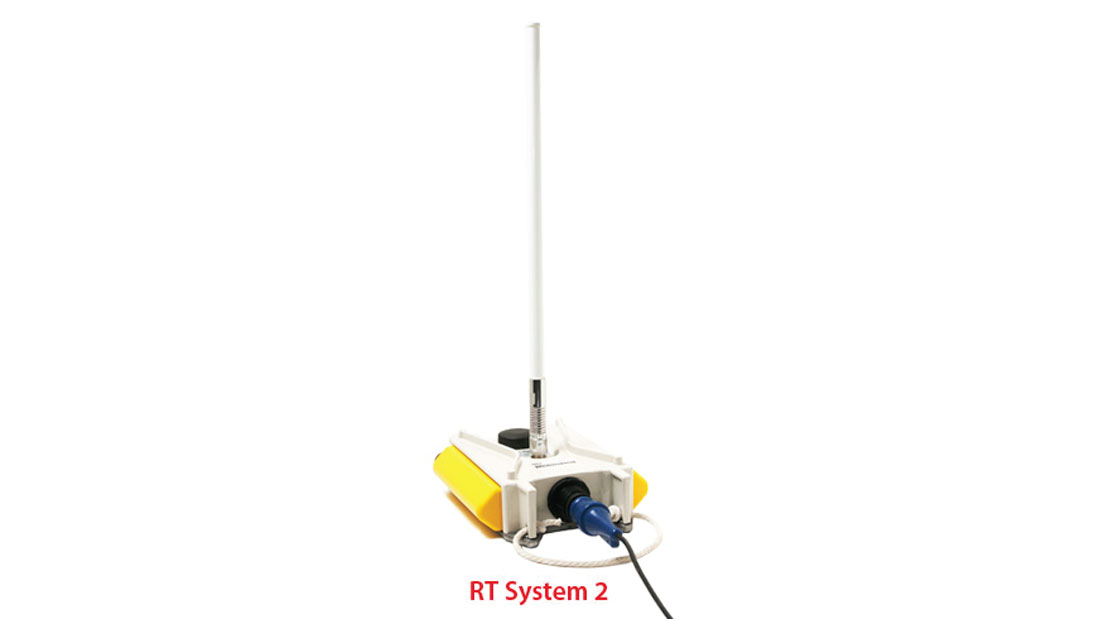

| 5 | Wireless Seismic – RT System 2 |

| 6 | iSeis – Sigma |

| 7 | Global – AutoSeis |

| 8 | Innoseis – TremorNet |

| 9 | Geophysical Technology Inc. – NuSeis NRU 1C |

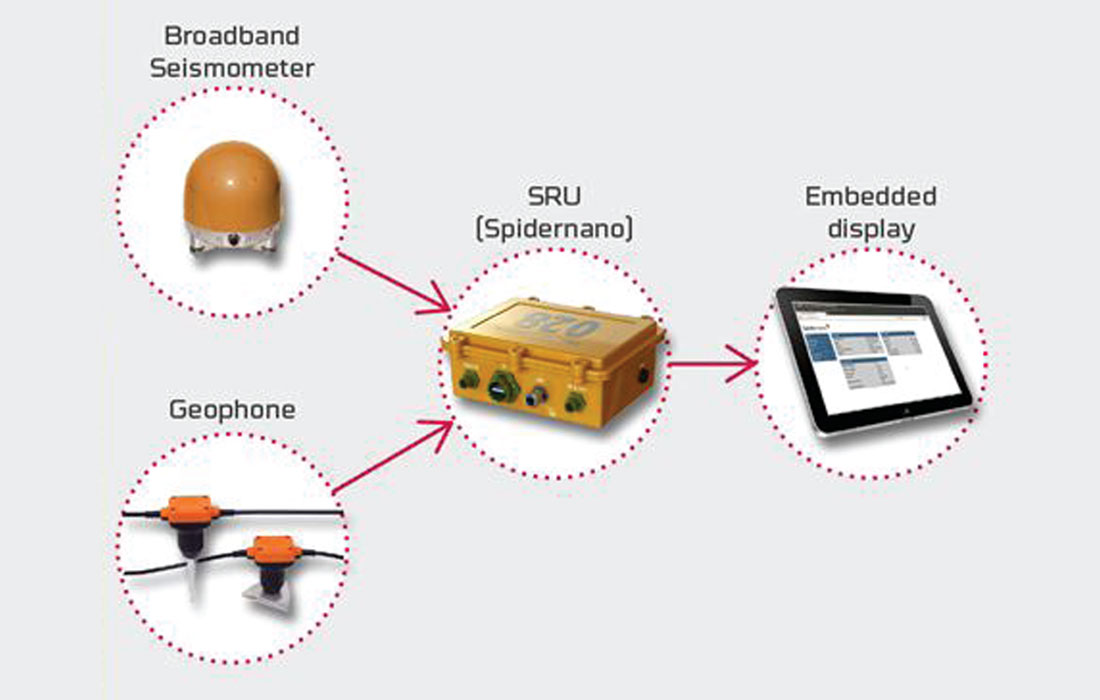

| 10 | WorldSensing – Spidernano |

Image 1: Inova – Hawk

“The Inova Hawk SN11 recording system is based on a wireless platform without radio infrastructure. It operates autonomously and is ideal for swift operations where visibility into the operation is not necessary. Hawk offers visual status checks through LED indicators and presents a user-friendly system for wireless data harvesting in the field,” Inova Website.

Image 2: Sercel – Unite

“Sercel Unite is a unique cable-free system that pushes back current acquisition limits to offer the best flexibility in the most challenging environments. Whether for data storage or real-time data transfer, using analog or digital sensors, its wireless QC and data harvesting capabilities off an unprecedented level of Flexibilty and quality control,” Sercel Website.

Image 3: FairfieldNodal – Zland

“FairfieldNodal ZLand nodes have always been lightweight, environmentally friendly, and easy to place and activate. They’ve always provided continuous, trouble-free recording with less equipment to deal with and minimal disruption to the environment. Now, ZLand nodes weigh even less and record even longer, typically 65 days (12 hrs/ day), for even greater productivity and savings,” FairfieldNodal Website.

Image 4: Geospace Technologies GSX

The GSX is designed for cable-free/radio-free seismic data recording. The self-contained unit in-cludes 1 to 4 channels of 32-bit digitization, an integrated/high sensitivity GPS receiver, built-in test signal generator, up to 32 GB per channel of non-volatile solid-state data storage, and a high-speed data port. The unit is housed in a sealed case, with input connector and extended life battery con-nector/data port connector.

Image 5: Wireless Seismic – RT System 2

“The RT System 2 is a revolutionary cable-free and real-time seismic data acquisition system that scales to tens of thousands of channels. RT System 2 delivers, at scale, the flexibility and reduced operating costs inherent in cableless systems, along with the well-understood advantages of real-time cabled systems, including data security and data visibility. Seismic contractors no longer need to sacrifice real-time data return and risk compromising the quality and the security of their data to get access to a high channel-count, cableless system,” Wireless Seismic Website.

Image 6: iSeis – Sigma

“Sigma™ is the most advanced, field-proven cableless acquisition system. It is a multi-mode stand alone recorder and also can be used side-by-side existing cabled hardware. It works seamlessly with Seismic Source Co, products and other controllers to provide the most fully integrated source control/recorder solution. It has already set records in passive as well as active acquisition,” iSeis Website.

Image 7: Global – Autoseis

“Amazingly productive, unbelievably simple, totally scalable, with no interconnecting cables or complex radio links between nodes, the AutoSeis HDR is a clear breakthrough in terms of crew productivity, data quality and reduced HSEQ risk,” Global Geophysical Services Website.

Image 8: Innoseis TremorNet

“TremorNet pushes the boundaries in wireless seismic sensor networks for on-shore oil and gas exploration and monitoring. Its ultra-low power technology means that each sensor node is significantly smaller and easier to handle, without compromising on sensing performance. This makes deployment and maintenance of large sensor networks simpler, faster and more cost efficient than cabled or other wireless systems,” Innoseis Website.

Image 9: Geophysical Technology Inc. – NuSeis NRU 1C

- Light Weight

- Lower Power Consumption

- Decreased Man Hours

- Minimal Environmental Footprint

- Decreased Operating Costs

- Automated Deployment and Retrieval

- High Quality vs Low Cost

- Leading Commercial terms

Geophysical Technology Inc. Website

Image 10: World Sensing – SpiderNano

“The Spider Remote Unit (SRU), thanks to its outstanding characteristics, offers Broadband Seismic Recording capabilities and storage from geophysical sensors. The SRU nodes are designed to be very simple to use and operate. They are very low power (only 0.5W), compact, light and robust. Its hardware is optimized for short field campaign as well as for permanent setup as monitoring stations,” Worldsensing Website.

Conclusions

Cableless seismic recording systems are becoming more common. They allow for greater productivity, cost savings and improvements in HSE. Their major perceived downfall is that they do not allow for real-time monitoring of the seismic spread and hence data quality. It is unlikely that cableless systems will completely replace the cabled version. However, it is likely that the different systems will be matched to the environment in which they are working. Some jobs may see both cableless and cabled systems combined and most acquisition companies will probably be offering both systems for a while to come.

Acknowledgements

The author wishes to thank Tesla Exploration Ltd for the opportunity to present these results and to the numerous companies included in this paper who have provided information and images of their cableless systems.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article