What a time to be asked to write an article about seismic acquisition! The prices of oil and gas have dropped off the map while the credit facilities of the world have all but closed their doors keeping capital investment in new projects at a stand still. Seismic being a cost with no immediate return on investment has seen large scale cut backs which came fast and furious in North America. I had asked what the Recorder would like to see in an article on Seismic Acquisition, the answer; “anything I wanted”. This is such a broad topic I could probably write a book on the round the world adventures this sector has brought to me. I shall attempt to keep it as local as possible.

I have had the opportunity to speak at my children’s’ schools more than once at a parent career day where different parents come in and talk about what they do for a living. I first volunteered when my son told his teacher I detonated explosives for a living, I thought it best I go in and clarify what seismic is. I based most of my presentation on mapping as it was the easiest way to keep things interesting for the students. An analogy I use to define seismic acquisition for a person that has no concept of what we do for a living is describing to them photography and the advances in technology that have been made in this art form over the past 60 years. Subsurface imaging is in essence a similar art form that has evolved at a similar rate.

Seismic exploration for Hydrocarbons in Alberta started in the 1940s. The instrumentation has evolved greatly from that time to present. Early seismic helped with the discovery of Pincher Creek and Leduc and later seismic has helped unlock the Horn River and the Oil Sands.

In the 1940s seismic data from the sensors was recorded directly to film or paper monitors. These monitors could not be processed any further except by hand. They were most often processed in the field by a field computer. Unfortunately this was not some multicore processor but a person with a pencil and ruler.

In the 1950s two big advances came along. AGC or automatic gain control allowed the gain of the amplifier to increase as the seismic energy of the shot decreased. The second was the magnetic recording of the sensor data. This allowed the data to be replayed with different processing filters.

In the 1960s we saw the big switch to digital data. No longer was the output of the analog sensor recorded as one long analog trace but as the now familiar 1s and 0s of digital data. This also totally changed processing of seismic data.

The 1970s saw the miniaturization, reliability and the channel count of the recording systems increased using the newly developed transistor. This was largely done using a seismic contractor’s electronics company which we know today as Texas Instruments.

The 1980s had an increase in channel counts and allowed us to investigate 3D seismic.

The 1990s gave us the 24 bit analog to digital convertor. This allowed even smaller electronics and the ability to move the recorder next to the geophone, the distributed recording system. This allowed even greater densities and larger size for 3D recording as well as greater operational efficiencies.

The 2000s gave us the digital sensor, Time lapse seismic and the introduction of the autonomous seismic recorder.

QHSE over the past few decades has evolved a great deal through the late 1980’s to today. 25 years ago records of safety statistics were not kept on a regular basis and environmental disturbances were hardly even considered. The two images displaying seismic operations from 1990 and 2005 show an extreme difference of environmental impact on a project. Although these projects are not in Canada, the level of QHSE globally has reduced its footprint substantially.

There is, however, something to be said about the reductions in line widths in certain areas of operations. A seismic acquisition project rarely takes place in a populated area with easy and quick access to all locations on the job site. The continual reduction of line widths makes our jobs more difficult to complete in a safe and efficient fashion. Operations in these reduced access areas take more time to execute in a safe manner therefore the total cost of the project is increased.

The goal is always to provide a quality product while reducing the foot print on the environment and not putting anybody in harms way. Through more stringent training of employees, continuously evaluating hazards on the job site and increased efforts on the proper use of personal protective equipment these goals are achievable.

One of the most challenging aspects of the seismic operations in Canada is the seasonal nature of the business. To maintain a high level employee to work in a window of roughly 100 days through the winter season is demanding. With the lack of year round work the industry is faced with a high turn over rate of employees and not enough young people entering the industry. The CAGC has worked hard to put forward recruiting campaigns to draw more interest from a new generation.

Another aspect of the short season in Canada is the management of change skills that Canadians learn. I cannot tell you how many clients we talk to want their job shot in February as this is the month with optimal weather conditions. Due to the extreme weather patterns in varying parts of the country scheduling and rescheduling takes place through the winter season to meet everyone’s needs. Changes in operations, procedures, equipment, facilities or personnel must be evaluated and managed to ensure that the total effect of the change is worth the effort and the final result is better for the people, environment and the client. These types of changes present themselves on a day to day basis. The efficiencies displayed by the field crews in change management aids them in taking their career beyond our borders where the acquisition market is stable and runs 12 months of the year for the most part. It is this skill set that makes Canadian Doodlebuggers an asset to any international company.

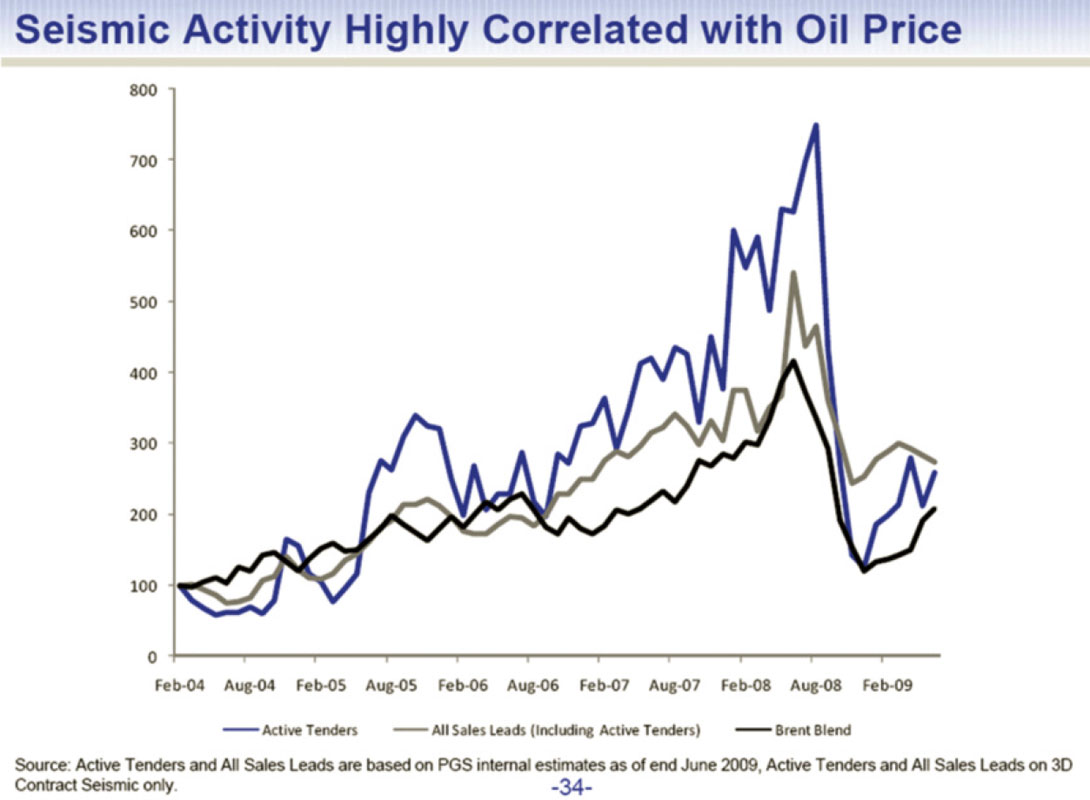

Seismic data is used by oil and natural gas companies as a risk management tool to reduce their drilling risk, and to more proficiently locate reservoirs and define oil and natural gas fields. Thus, demand for seismic services is driven by the Exploration & Production (E&P) activity, which is in turn is driven by the price of oil, natural gas and final consumer demand. The land seismic segment in Canada is driven more by natural gas prices due to increasing shale activity; whereas the marine seismic segment is almost entirely dictated by the price of oil.

On an intellectual level, seismic surveying is like an insurance policy for a project. The value is especially high due to its relatively low marginal cost (typically less than 5% of the total project cost), and the vital role it plays in determining the economic viability of a project.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article