Visualization and virtual reality technologies conjured up visions of elitist, other-worldly usage when they first gained notoriety for oil industry purposes in the mid-1990s. However, such applications rather quickly morphed from the perceived esoteric realm to the everyday, becoming almost de rigueur now for any number of E&P uses.

Still, certain misconceptions remain.

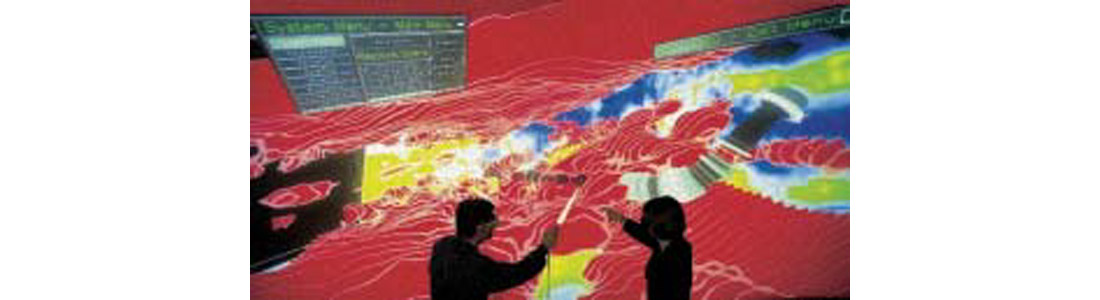

Virtual reality, in fact, is far more than just visualization, even though the two terms are used interchangeably more often than not. Perhaps the most distinctive difference is the sense of immersion and accompanying perception of depth that characterizes virtual reality-owing primarily to the combination of large screens, stereo display and the type of user interface.

Virtual Reality...A computer-generated artificial world where users are immersed in the environment and can navigate and interact with objects in an intuitive and natural manner.

In the standard big-screen visualization environment, the computer/mouse interface acts as a natural barrier to conversation and interaction between the “operator” and other users. Virtual reality, however, employs a head-tracking system and wand to connect the user to the virtual world. The user explores and interacts with the viewable objects through natural body movements, such as walking and turning the head, e.g., bending to look underneath or behind the display. In other words, intuitive gestures like walking, pointing, grabbing and drawing replace clicking and typing.

Another common misconception about these technologies is that they are useful only for interpretation of large volumes of seismic data for exploration purposes. In fact, dedicated virtual reality software is now being used to streamline the drilling and production milieu.

The InsideReality® 3D virtual reality technology system recently was introduced into the marketplace, with a proven track record for successful well planning and geosteering. The benefits of such activity include increased sand penetration and increased hydrocarbon production, which directly impact well profitability. In one field alone, use of the virtual reality environment reduced time expended by 100 days and increased income by $86 million.

Initially conceived in 1996 as a research project at Norsk Hydro, the technology was developed under the aegis of both Norsk Hydro and Christian Michelsen Research. Ultimately, it was spun off as a separate company – InsideReality – which was purchased by Schlumberger Information Systems in 2002.

Today the software is being used in development work for the most part where seismic volumes are smaller than in exploration. Norsk Hydro uses this system on all its major fields in Norway and recently brought the technology to the Gulf of Mexico by installing a system in its new office in Houston.

The tool was designed for decision-making based on technical data rather than for interpretation application. Used in both the production planning and drilling phases, it looks at geophysical and geological data to better understand field geology and to acquire more accurate information about the reservoir and its complexities to enable well path planning and geosteering even in the most complex horizontal wellbore.

Virtual reality is elevated to a whole new level through the extreme immersion achieved with Inside Reality via large screens, stereo display and head/hand tracking, which give the feeling of “being inside”. The system can be used in a variety of physical setups, i.e., flat wall, curved screen, CAVE, and little more than a day is required for someone to learn to operate it. An OpenSpirit data access interface provides rapid connection to industry standard databases.

Once “inside” the data display, participating team members from varied disciplines can interact with the data to produce new products and workflows not possible with ordinary workstation software. For example, new well paths can be drawn directly in 3D space, optimally positioned relative to 3D seismic, geological models and other data. Real-time update of drillability calculations enables the design and planning of the most expedient well path.

Team members can understand relationships among the various data types and grasp complex 3D concepts quicker for faster, more accurate decisions within a highly collaborative environment- the driller, the engineer, the geoscientist all speak the same language.

While other tools are available to the oil and gas industry to enable users to see the data in 3D in a collaborative environment, the exceptional degree of immersion afforded by Inside Reality is a distinguishing feature positioning it at the forefront of this technology where it has demonstrated substantial real dollar value. An apt analogy to its immersive power would be to compare the illumination afforded by a candle to that which is possible using an electric light bulb. One can see objects and read text using the light from the candle, but true clarity is achieved only with the electric bulb.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article