Summary

The first test of passive seismic technology at Imperial Oil’s heavy oil operation in Cold Lake, Alberta was conducted in 1995. Since 1998 passive seismic monitoring has been integrated into the commercial operations. There are currently ~100 dedicated monitoring wells with 5, 8, 10 or 12 tri-axial geophones deployed in each well at depths ranging from 50 to 400 meters. The main objective of the monitoring is to detect casing failures and inadvertent fluid releases into the overlying shales or aquifers to mitigate environmental consequences. The passive seismic monitoring is intimately connected to the operations of the field with daily interaction between the seismic analysts and operations personnel, along with a systematic response plan that ensures appropriate operational interventions are taken when passive seismic alarms occur.

One of the main challenges associated with operating a permanent passive seismic network within a producing oilfield is managing the large data flow and analyzing the data within 24 hours, seven days a week, 52 weeks a year. Large quantities of noise events are generated, with the seismic events of interest buried within. Data reduction is achieved with processes to reduce noise triggers, to filter triggered noise events to determine if the trigger criteria are still met. Continuous channel statistics are also used to identify periods of activity and possible depths of interest. Site specific software controls the data management and allows for seamless review of the daily statistics and analysis of the seismic events. Triggered events are classified as small earthquakes, casing failures, cement cracks, fluid movements, rod noise, or surface operations. Interventions in operations are specified in a code of practice. The passive seismic monitoring is an integral part of maintaining the license to operate.

Whilst the main effort is devoted towards the use of passive seismic monitoring for managing the casing and overburden integrity aspects of the operation, we have carried out experiments with geophones located just above the reservoir. These experiments were aimed at understanding steam movement in the oilsand reservoir interval. Significant insight was gained regarding event locating techniques when using multiple downhole arrays. Microseismic patterns aligned with the regional stress field demonstrate that the steam movement is controlled primarily by the stress state in the reservoir.

Introduction

Passive seismic monitoring is applied at Imperial Oil’s Cold Lake heavy oil operation in Alberta to detect the inadvertent release of production fluids into formations overlying the oilsand reservoir. This fluid release can occur as a result of a casing break or by fluids migrating from the oilsand reservoir along a channel in the cemented annulus outside the casing. In either case, the resulting release of production fluids has the potential to contaminate aquifers, breach to the surface, or destabilize an overburden layer increasing the risk of future operations (Smith et al., 2001). The consequences of these events can be mitigated through early detection and intervention.

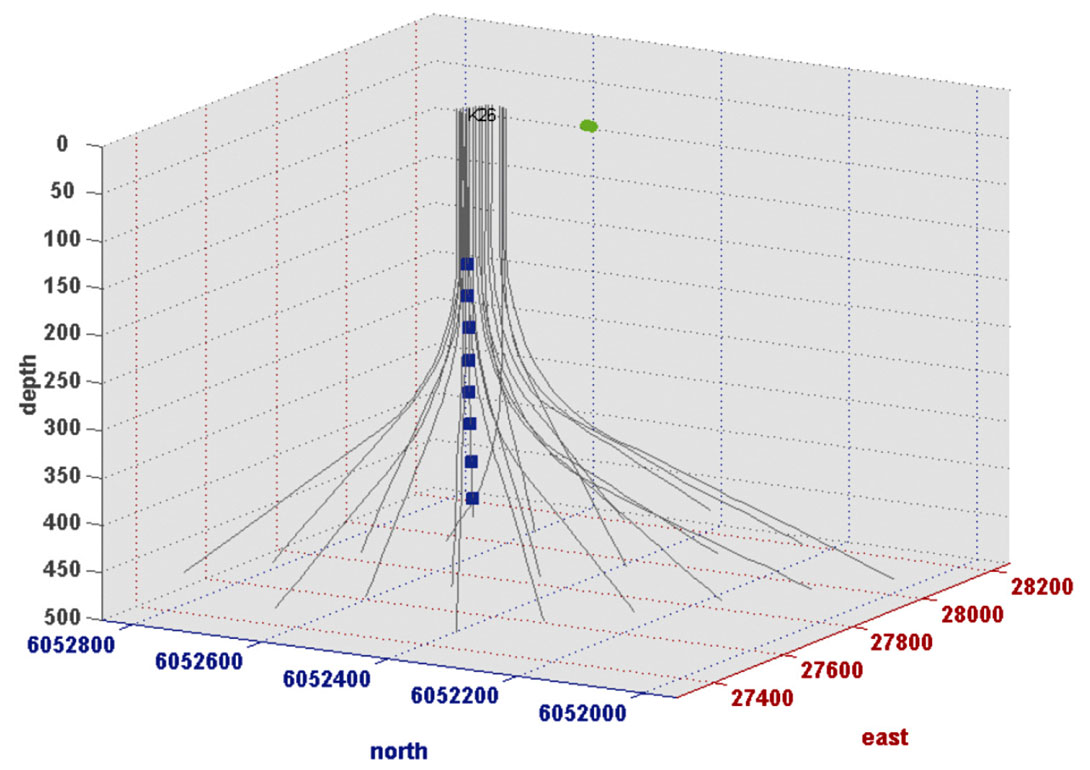

The Cold Lake field has approximately 4000 wells using Cyclic Steam Stimulation to extract bitumen from the oil sands formation at approximately 450 m below surface. Steam is injected at formation fracture pressure to reduce the bitumen viscosity so it can be pumped to surface. The production wells are drilled on 4 or 8 acre spacing in groups of 20-40 from a common surface location called a “pad” and are used for both steam injection and bitumen production. Reservoir dilation during steam injection causes the overburden to heave which can result in microseismic events. In order to detect these events, a dedicated passive seismic monitoring well is located on each pad with 5 to 12 tri-axial geophones deployed at depths spanning about 50- 400 m. A typical pad layout is shown in Figure 1.

Large amounts of data, sometimes thousands of event files, can be generated on a daily basis by these monitoring wells. Data reduction is achieved with programmable trigger settings to reduce spurious noise events, automated filtering of noise events that are recorded, and by generating channel specific statistics. Each day the genuine seismic events are analyzed for the source locations, classified according to seismic attributes, and reported to the operations staff. Examples of event types detected during normal operations are casing failures, cement cracks, shear events associated with heaving the formation, and various noise types associated with the production operations. The most prevalent noise events are generated by rod pumps in the production wells. Since these rod noise events can originate from various depths along the wells, they can obfuscate the genuine events, so processes to eliminate or filter these events are necessary. Casing failure events have a unique seismic signature that distinguishes them from normal shear events (Talebi et al., 1998). The casing failure model has proven to be robust with a detection success rate of greater than 80% (Smith et al., 2002). The passive seismic systems have been so successful in casing failure detection that the system design was upgraded to make this a primary role. On rare occasions, events associated with a shallow fluid release have also been observed. A pilot test in 1995 and follow-up field test in 2002 demonstrated that fluid release into the overlying shales is characterized by multiple shear events located along the plane of injection and by small amplitude, high frequency events associated with fluid flow in a fracture. The latter events tend to occur in bunches in rapid succession and are referred to as continuous microseismic radiation (CMR). Appropriate operational responses based upon the seismic analysts’ daily reports are implemented and can include shutting down steam injection to investigate potential casing failures and fluid releases. Passive seismic monitoring has become a critical part of the casing integrity monitoring at Cold Lake, improving the overall safety and operability of the field.

System Design and Data Handling

A software based STA/LTA trigger algorithm is used for event detection in the continuous record. The large and varied amount of data recorded over the years has allowed the trigger settings to be optimized for capturing genuine seismic events and minimizing the number of noise triggers. To ensure that a record of the waveforms is available in the absence of triggered data, regular periodic event files are recorded each hour. During an investigation this frequency is increased and the periodic events are analyzed for CMR type events which may not have triggered the system. A rolling data buffer consisting of 7-14 days of continuous data is available for analysis in recent installations.

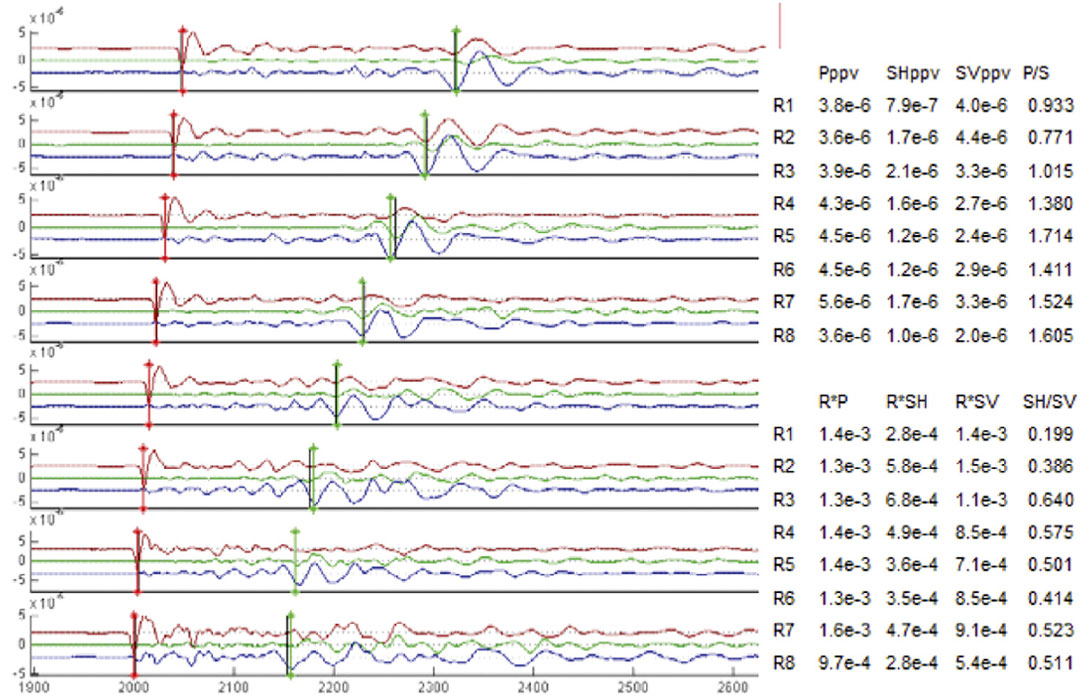

A web based server automates the data management and remote system control of the pad computers. This web server is critical for management of the massive amount of data captured on a daily basis. A source location and attribute analysis program (Bailey et al., 2008) incorporates seamless data transfer from the web server for event file analysis. Source locations are based on P and S wave arrival time matching and hodogram analysis. Layered velocity models are pad specific and are reasonably well constrained with sonic logs, calibration shots and matching source locations of historical casing failures.

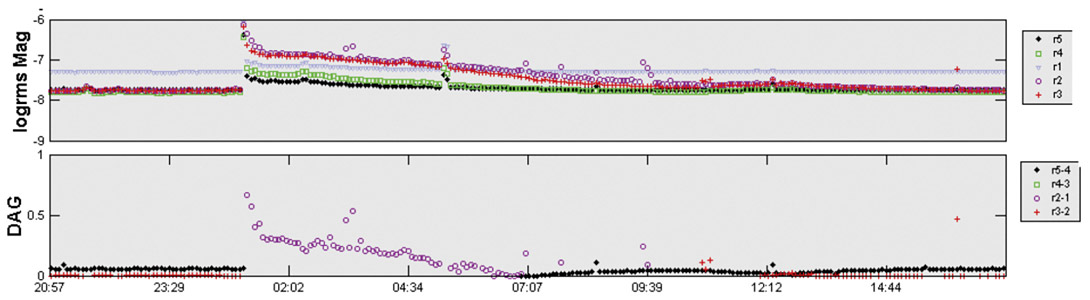

Data reduction is critical to the identification of genuine events in the presence of significant environmental noise. Channel specific statistics of the average and peak amplitude of both the raw and bandpass filtered data are computed every five seconds as a snapshot of the continuous seismic record. A parameter called the Differential Acoustic Gradient (DAG) is computed to identify inversions of the acoustic gradient by comparing the energy between adjacent geophone levels. This analysis is used to identify the existence of possible seismic sources which may not trigger the acquisition system to generate an event file. These small events may be the CMR events associated with a fluid release. An example of this analysis is shown in Figure 2.

Typical Event Types and Responses

There are a number of event types recorded by the passive seismic systems at Cold Lake. Genuine events originate in the rock formations due to stresses induced by steaming and production operations, casing failures, or fluid releases. Most of the formation events that are recorded are considered benign. Noise events are a result of human or mechanical activity at surface or in the subsurface wells.

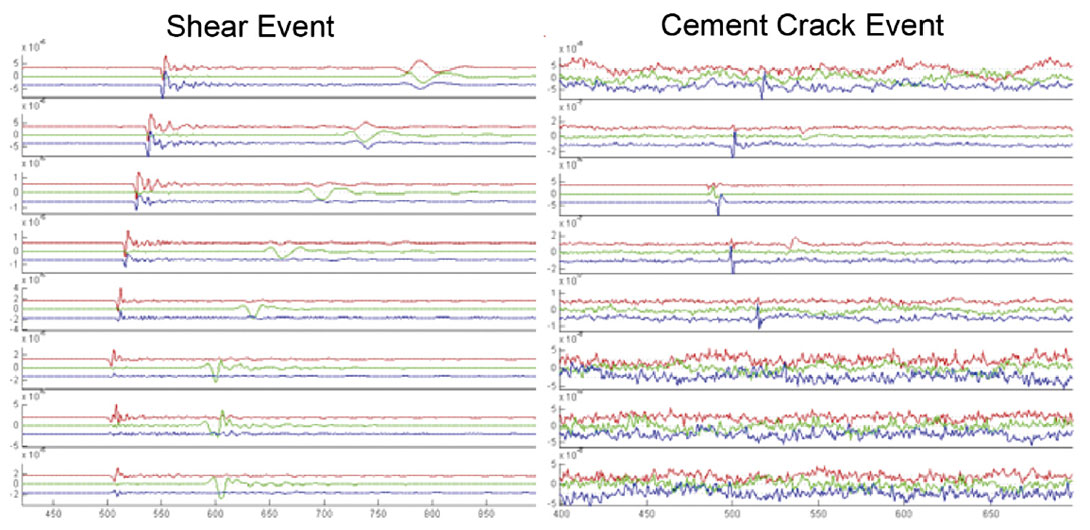

Reservoir dilation during steam injection causes the overburden to heave imparting incremental stresses which can result in shear events associated with slip along bedding boundaries or natural fractures. An example of a waveform from a typical shear event is shown in Figure 3. Most heave-induced shear events can be correlated with the steam injection on a given pad. The thermal aspect of the operation also results in small cement crack events due to differential expansion of the steel casing and the cement sheath around the casing. These events typically occur near the beginning of steam injection and are low energy impulsive events with little or no shear wave associated with them. An example is shown in Figure 3.

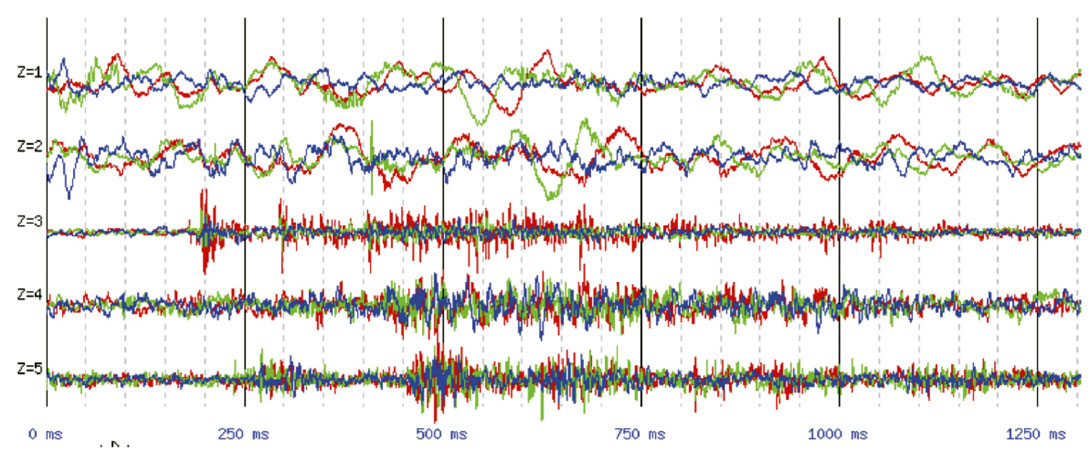

Induced seismicity can also be a result of production activity associated with surface facilities, rig work and downhole rod pumps. The rod pump noise is particularly pervasive, accounting for over 90% of the triggered event data collected. The rod noise is typically characterized by a combination of emergent and impulsive arrivals originating at multiple depths. An example of rod noise is shown in Figure 4. Fortunately these events are usually characterized by higher frequencies and a consistent periodicity aligned with rod pump stroke timing allowing them to be identified more easily. However, the existence of large numbers of rod noise events can obfuscate the detection of shear events and CMR type events. During times when some wells on a pad are steaming and others are pumping, the pumps will be shut-in periodically to allow for quiet times to investigate the possibility of ongoing fluid release events that are too small to trigger the system or may be lost in the rod noise.

Casing failures typically manifest themselves as a sudden parting of the casing resulting in axial movement of the production casing relative to the surrounding material. Typical casing failure events have large amplitudes, a P/S ratio close to unity, and a Sh/Sv ratio of about 0.5 or less due to the polarization of the S-wave along the wellbore axis. An example casing failure waveform is shown in Figure 5. When shallow casing failures are detected while the reservoir is at high pressure, steam may be shut-in and reservoir depressurization may be initiated in order to kill the well. The specific interventions to be adopted depend on several operational variables and the governing code of practice. Sometimes fluid may flow back from the reservoir into the break and it may be difficult to determine the depth of the break from conventional methods. In these cases the break depth estimate obtained from the seismic event source location aids operation personnel to expeditiously determine well kill procedures.

Reservoir seismicity patterns

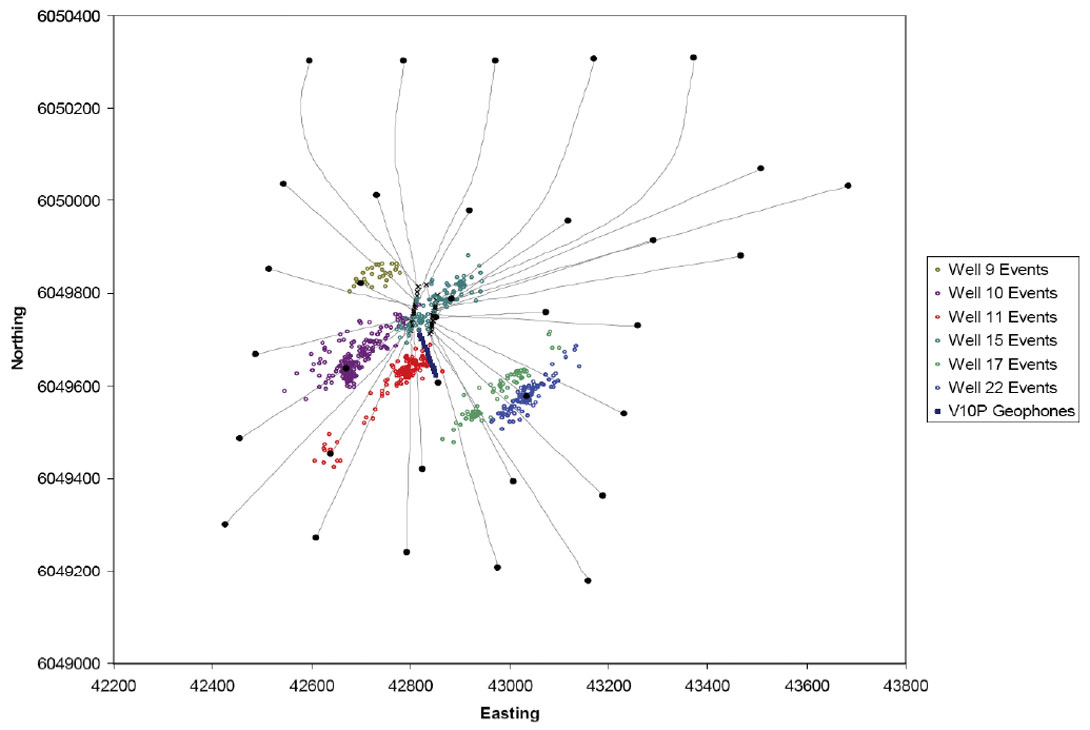

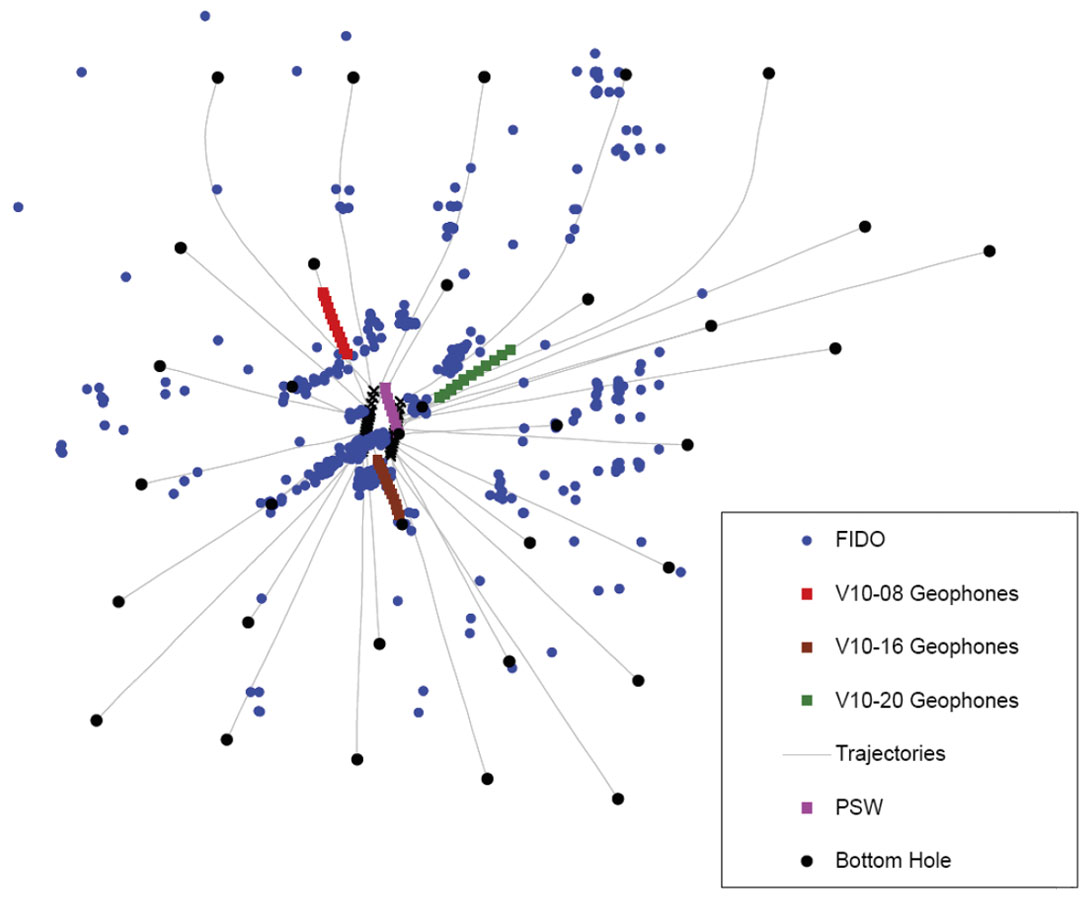

For the first and second steaming cycles of a new pad at Cold Lake, temporary geophone arrays, in addition to the permanent system, were installed just above the reservoir interval. For the first cycle, only one array was installed and for the second cycle, three arrays were installed. Figure 6 shows the seismicity maps for the first cycle for events located in the oilsand formation only. The seismic events have been plotted by colour to show the steaming well interpreted to be the source. Note that the seismic lineations are aligned along the NE-SW direction. The second cycle, with 3 temporary arrays, has greater sensitivity to small events in a larger part of the reservoir than the single system in the first cycle. The cycle 2 seismicity is shown in Figure 7. One can see that the seismicity lineations have the same orientation in both cycles but that the deformation zones active in the first cycle are not necessarily active in the second.

Conclusions

Passive microseismic monitoring is a key requirement for Imperial Oil’s license to operate a high pressure thermal recovery process at Cold Lake, Alberta. The monitoring provides a system for detecting casing failures and inadvertent fluid release into overlying formations. The system is extensive, with about 100 dedicated monitoring wells with five to ten tri-axial geophone receivers each. Systems and processes are in place to manage the large amount of data generated. These allow the efficient detection of genuine microseismic events in the presence of significant environmental noise associated with the production operations. This case study demonstrates that passive seismic monitoring can be implemented in an operating field and can provide tangible value to improve operating well integrity. Furthermore, it has been demonstrated that monitoring the oilsand reservoir during injection provides the possibility of mapping out the steam paths in the reservoir.

Acknowledgements

A version of this abstract was first presented at the EAGE Passive Seismic: Exploration and Monitoring Applications Workshop in Dubai, United Arab Emirates, 10 - 13 December 2006. The following people are acknowledged for their contribution; Colum Keith, Jeff Bailey, Zack Lawrence, Anu Venkataraman, Marc Chen, Simona Costin, Henry Bland, Rick Kry, Tom Boone, Shahriar Talebi, Martin Cote and Russell Boyle.

Join the Conversation

Interested in starting, or contributing to a conversation about an article or issue of the RECORDER? Join our CSEG LinkedIn Group.

Share This Article